In the ever-evolving landscape of modern industry, material selection is paramount. Components must withstand extreme environments, exhibit exceptional durability, and ensure safety—challenges that have made high-performance materials indispensable. Among these, polytetrafluoroethylene hoses (PTFE hoses) stand out for their unique combination of properties, emerging as a cornerstone in diverse industrial sectors.

A Paragon of Chemical Stability

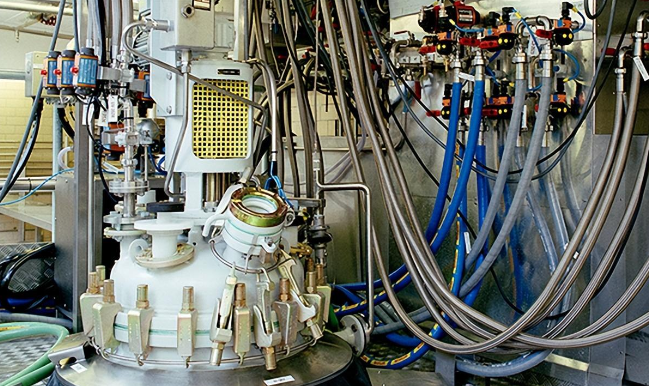

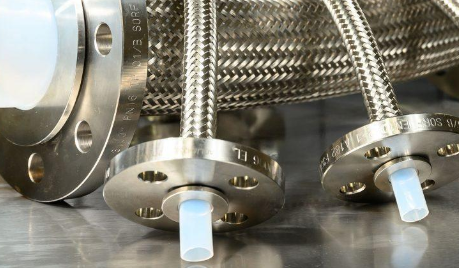

PTFE hoses are renowned for their unmatched chemical resistance. Virtually impervious to degradation by any chemical substance, they endure exposure to strong acids, alkalis, organic solvents, and other corrosive media without compromising their structural integrity or performance. This trait is particularly critical in the chemical industry, where transporting highly corrosive fluids demands reliability. Whether handling acidic solutions, alkaline compounds, or volatile solvents, PTFE hoses maintain stability, setting a standard for chemical resilience.

Exceptional Temperature Resistance: Adaptable in Extremes

Beyond chemical stability, PTFE hoses excel in tolerance to extreme temperatures, operating reliably across a wide range from -70°C to 260°C—with the ability to withstand short-term spikes beyond this range. This versatility makes them ideal for environments where temperature fluctuations are severe, such as aerospace applications (where components face both scorching heat and freezing cold) or industrial setups in frigid regions. Their consistency in performance ensures seamless media transport, even in the harshest thermal conditions.

Safety as a Priority

Safety is a hallmark of PTFE hoses, particularly in hazardous environments. Their non-conductive nature prevents electrostatic discharge, making them explosion-proof when conveying flammable or explosive media. This feature is invaluable in industries like oil and chemicals, where the risk of ignition is high. Additionally, their excellent electrical insulation properties position them as a top choice for applications requiring robust dielectric performance, further expanding their utility in electrical and electronic sectors.

Durability Drives Cost-Efficiency

The cumulative advantages of PTFE hoses—chemical inertness, thermal stability, and mechanical resilience—translate to extended service life. By minimizing the need for frequent replacements and maintenance, they significantly reduce operational costs, offering a compelling economic case for industries reliant on long-term, stable operations. For machinery and systems that demand uninterrupted functionality, PTFE hoses are a strategic investment, enhancing both reliability and cost-effectiveness.

PTFE Hoses: Transforming Diverse Industrial Landscapes

From chemical processing and aerospace to automotive manufacturing and pharmaceuticals, PTFE hoses have become irreplaceable. Their ability to integrate seamlessly into critical workflows—safeguarding processes, enhancing efficiency, and ensuring safety—cements their role as a versatile industrial essential. As industries continue to prioritize performance and sustainability, the demand for PTFE hoses is set to grow, solidifying their status as a cornerstone of modern manufacturing and engineering.

For more insights into how PTFE hoses can revolutionize your industrial operations, stay tuned for updates on cutting-edge material solutions.

This article highlights the unmatched versatility of PTFE hoses, underscoring their value across sectors that demand reliability in the face of rigorous challenges.

Post time: Jun-20-2025