Choosing the right hydraulic hose fittings is crucial for high-pressure systems. Leaks and failures can waste millions of gallons of hydraulic fluid annually, costing tens of thousands of dollars per system. Beyond the financial hit, unplanned downtime disrupts operations and increases maintenance expenses. Regular inspections and using fittings that meet SAE J517 or EN standards can prevent these issues. For instance, a mining operation improved reliability by redesigning hose layouts and adding abrasion sleeves, tripling hose life. The right fittings not only enhance safety but also help systems run more efficiently and cost-effectively.

Key Takeaways

- Picking the right hydraulic hose fittings stops leaks and breaks. This avoids expensive repairs and wasted time.

- Know the difference between permanent and reusable fittings. Permanent ones are strong for high pressure, while reusable ones are handy for quick fixes.

- Always match the fitting’s pressure rating to your system’s needs. If they don’t match, big problems can happen.

- Make sure the fitting material works with the hydraulic fluid. This helps it last longer and stops leaks.

- Think about things like heat and rust when choosing fittings. This makes your system work better and last longer.

Types of Hydraulic Hose Fittings

Hydraulic hose fittings come in various types, each designed to meet specific system requirements. Choosing the right type ensures better performance and longer system life. Let’s explore two common categories: permanent and reusable fittings.

Permanent Hydraulic Hose Fittings

Permanent hydraulic hose fittings are crimped onto the hose using specialized equipment. These fittings create a secure, leak-proof connection, making them ideal for high-pressure applications. Industries like construction, mining, and agriculture often rely on these fittings due to their durability and reliability.

One standout feature of permanent fittings is their ability to handle extreme conditions. For example, compact hydraulic hoses paired with permanent fittings can exceed twice the ISO 18752 standard for pressure impulses. Some hoses, like Parker’s 787TC and 797TC series, are rated for constant pressures of 35.0 MPa (5,000 psi) and 42.0 MPa (6,000 psi), respectively. These hoses have been tested to withstand two million impulse cycles, even at smaller bend radii than required by ISO standards. This level of performance makes permanent fittings a top choice for demanding environments.

Reusable Hydraulic Hose Fittings

Reusable hydraulic hose fittings, as the name suggests, can be removed and reattached. These fittings are threaded onto the hose, eliminating the need for crimping tools. They’re a practical option for field repairs or systems requiring frequent maintenance.

While reusable fittings may not match the pressure ratings of their permanent counterparts, they offer flexibility and cost savings. Operators can quickly replace damaged hoses without specialized equipment, reducing downtime. This makes them a popular choice for smaller systems or applications where portability is key.

Both types of hydraulic hose fittings serve unique purposes. Understanding their strengths helps operators select the best option for their specific needs.

Common Coupling Interfaces for High-Pressure Systems

Hydraulic systems rely on coupling interfaces to connect hoses and components securely. These interfaces play a critical role in maintaining system integrity under high pressure. Let’s explore three common types: threaded couplings, mated angle couplings, and O-Ring Boss (ORB) designs.

Threaded Couplings

Threaded couplings are among the most widely used interfaces in hydraulic systems. They feature male and female threads that screw together to form a tight seal. Their simplicity and reliability make them a go-to choice for many industries.

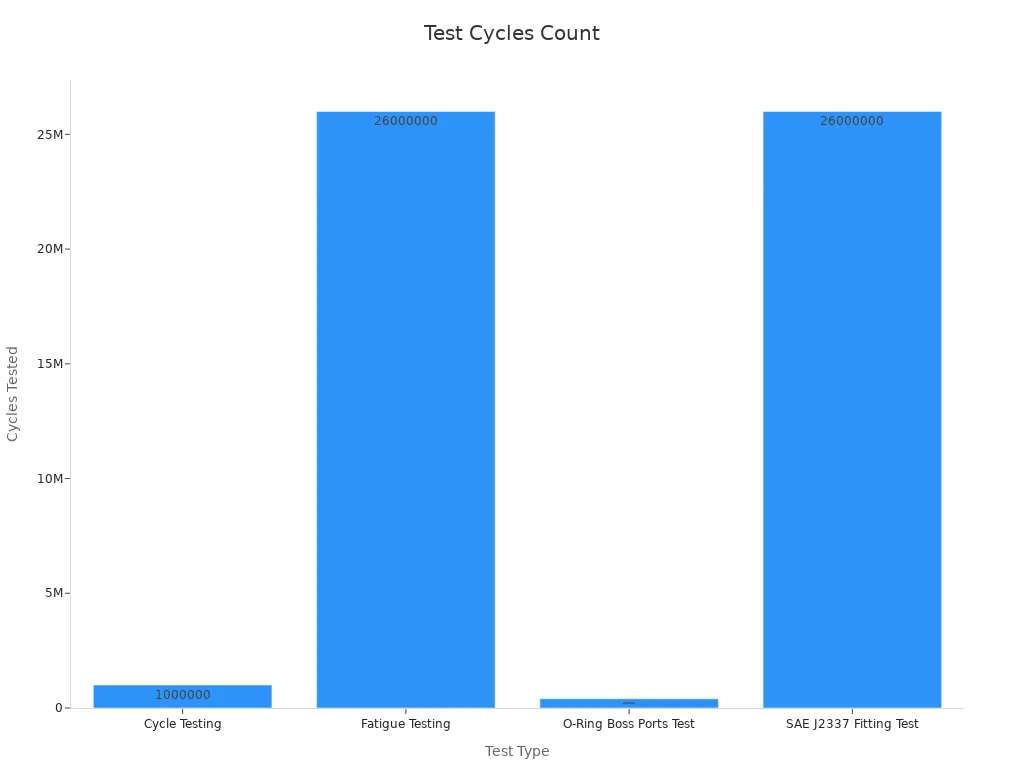

Engineering tests highlight their durability. For instance, cycle testing on threaded couplings showed no damage after one million cycles, while fatigue testing revealed no failures even after 26 million cycles. These results demonstrate their ability to withstand extreme conditions. However, O-ring boss ports tested under similar conditions experienced cracks after 400,000 cycles, emphasizing the importance of selecting the right coupling for specific applications.

Mated Angle Couplings

Mated angle couplings use angled surfaces to create a seal. These couplings are ideal for systems requiring precise alignment and minimal leakage. Their design reduces the risk of pressure fluctuations, which can lead to hydraulic resonance. Research shows that optimizing mated angle couplings can reduce pressure fluctuations by 73% at the pump end and lower maximum fluctuation amplitude by 59.3%. This makes them a reliable choice for high-pressure applications.

| Aspect | Details |

|---|---|

| Focus | Performance differences in high-pressure common rail systems |

| Key Findings | Pressure fluctuations and hydraulic resonance observed; optimization reduced fluctuations significantly |

| Results | 73% reduction in fluctuations at the pump end; 59.3% reduction in maximum pressure fluctuation amplitude |

| Methodology | Time-domain and frequency-domain analyses conducted; theoretical foundation for structural design provided |

O-Ring Boss (ORB) Designs

ORB fittings are designed for medium to high-pressure systems. They use synthetic rubber O-rings to prevent leaks, making them a popular choice in industries like oil and gas. These fittings offer a highly reliable connection due to their elastomeric seal, which ensures a leak-free system. Manufacturers often prefer ORB designs over NPT ports for their superior performance and design flexibility.

Under high-pressure conditions, the material and design of the O-ring are critical. A well-designed ORB fitting can handle varying pressure levels without compromising its integrity. This reliability reduces maintenance needs and enhances equipment durability, making ORB fittings one of the best options for high-pressure hydraulic systems.

Key Considerations for Selecting Hydraulic Hose Fittings

Choosing the right hydraulic hose fitting involves more than just picking a part that fits. It requires understanding the system’s needs and the conditions it will face. Let’s break down three key factors to consider: pressure rating, material compatibility, and environmental factors.

Pressure Rating

Pressure rating is one of the most critical aspects when selecting a hydraulic hose fitting. A fitting must handle the system’s maximum operating pressure without failure. But how do manufacturers determine these ratings? They rely on rigorous testing methods, such as:

- Burst Tests: These simulate extreme pressure spikes. For example, a fitting rated at 5,000 psi must withstand over 20,000 psi during testing.

- Cyclic Endurance Tests: These mimic repetitive pressure changes, testing components at 1.25 to 1.33 times their rated pressure for at least 100,000 cycles.

- Industry Standards: Standards like SAE J343 and NFPA T6.1 ensure fittings meet strict safety and performance criteria.

Statistical analyses also play a role. For instance, burst testing involves testing multiple samples to calculate the average burst pressure and its standard deviation. This ensures fittings can handle unexpected surges, keeping hydraulic systems safe and reliable.

Tip: Always check the pressure rating of a fitting against your system’s requirements. A mismatch can lead to leaks, failures, or even catastrophic damage.

Material Compatibility

The material of a hydraulic hose fitting must be compatible with the fluid it will carry. Different fluids have unique properties that can affect the fitting’s performance. For example, some fluids may cause seals to degrade over time, leading to leaks.

Research highlights the importance of testing seal materials with specific hydraulic fluids under real-world conditions. Standardized tests might not always reveal how materials perform in dynamic systems. Comprehensive testing helps engineers understand how seals wear and interact with fluids, ensuring long-term compatibility.

Here’s how to ensure material compatibility:

- Identify the fluid used in your system.

- Consult manufacturer compatibility charts.

- Test the material if unsure about its performance.

- Consider the long-term effects of fluid changes.

Note: Manufacturers often provide detailed technical data sheets. These documents outline key specifications, including material compatibility, to help you make informed decisions.

Environmental Factors

Environmental conditions can significantly impact the performance and lifespan of hydraulic hose fittings. Factors like temperature, humidity, and exposure to corrosive elements must be considered. For example, fittings in high-temperature environments need to withstand heat without degrading, while those in corrosive settings require materials like stainless steel or brass.

The table below highlights recommended materials for different environmental conditions:

| Environmental Condition | Recommended Material |

|---|---|

| Corrosive Environments | Corrosion-resistant materials like stainless steel or brass |

| High-Temperature Environments | High-temperature alloys or thermoplastics |

| Other Environmental Factors | Materials that endure UV radiation, extreme cold, or abrasives |

Pro Tip: Evaluate the environment where the fitting will operate. Choosing the right material can prevent premature wear and reduce maintenance costs.

By considering these factors—pressure rating, material compatibility, and environmental conditions—you can select hydraulic hose fittings that enhance system performance and reliability.

Top Hydraulic Hose Fittings for 2025

ORFS Fittings: Features, Advantages, and Ideal Applications

ORFS (O-Ring Face Seal) fittings are a top choice for high-pressure hydraulic systems in 2025. These fittings use an elastomeric O-ring to create a leak-proof seal, making them ideal for applications where reliability is critical. Industries like oil and gas, aerospace, and manufacturing rely on ORFS fittings to maintain system integrity under extreme conditions.

One of the standout features of ORFS fittings is their ability to resist vibrations and torque. This makes them perfect for systems that experience constant movement or pressure fluctuations. For example, ORFS fittings have been used in helium compressor systems to fill 20 cylinders in just seven minutes, significantly boosting efficiency. They also play a key role in CO₂ refrigeration systems, ensuring leak-free connections that comply with environmental standards.

| Metric/Case Study | Description |

|---|---|

| Leak-Proof Connections | ORFS fittings ensure leak-free connections in high-pressure hydraulic systems. |

| Vibration Resistance | Maintains sealing integrity under extreme torque and vibrations. |

| High Pressure Capability | Can reliably contain gases at pressures up to 7,500 psi. |

| Helium Compressor Systems | Enabled a 20-cylinder helium fill in 7 minutes, improving efficiency significantly. |

| CO₂ Refrigeration Systems | Ensured leak-free connections critical for environmental compliance and system efficiency. |

Tip: ORFS fittings are a great option for systems requiring high-pressure capabilities and vibration resistance. Their reliability reduces downtime and maintenance costs.

Bite Type Compression Fittings: Features, Advantages, and Ideal Applications

Bite type compression fittings are another excellent choice for hydraulic systems in 2025. These fittings use a ferrule that “bites” into the tubing, creating a secure and durable connection. Their design ensures high-pressure performance and ease of installation, making them popular in industries like construction, automotive, and heavy machinery.

These fittings excel in applications where space is limited. Their compact design allows them to fit into tight spaces without compromising performance. Bite type compression fittings are also known for their versatility. They work well with various tubing materials, including steel, stainless steel, and copper, ensuring compatibility across different systems.

| Aspect | Details |

|---|---|

| Compact Design | Ideal for systems with limited space. |

| Versatility | Compatible with steel, stainless steel, and copper tubing. |

| High-Pressure Performance | Reliable under extreme pressure conditions. |

| Ease of Installation | Quick and straightforward setup. |

These fittings are perfect for applications requiring frequent maintenance or adjustments. Their simple installation process saves time and reduces labor costs, making them a cost-effective solution for many industries.

Pro Tip: When selecting bite type compression fittings, consider the tubing material and pressure requirements to ensure optimal performance.

Parker Face Seal Fittings: Features, Advantages, and Ideal Applications

Parker Face Seal fittings are renowned for their reliability and versatility in modern hydraulic systems. These fittings use an O-ring face seal to provide a secure connection, even under high-pressure conditions. Their robust design makes them suitable for industries like agriculture, mining, and energy.

One of the key advantages of Parker Face Seal fittings is their wide range of operating pressures and temperatures. They can handle pressures up to 6,000 psi for smaller sizes and temperatures ranging from -30°F to 400°F, depending on the seal material. This flexibility allows them to perform well in diverse environments, from freezing temperatures to high-heat applications.

| Feature | Specification |

|---|---|

| Maximum Operating Pressure | 6,000 psi (up to 1 in.) |

| 4,000 psi (1.25 and 1.50 in.) | |

| Temperature Range | -30 to 250°F (Nitrile) |

| Up to 400°F (Fluorocarbon) | |

| Pressure Range | 1,450 to 9,100 psi |

| Sealing Mechanism | O-ring face seal |

| Compatibility | Various fluids and temperatures |

| Installation Method | Mechanical (flanging) or brazing |

| Tube Wall Thickness Range | Exceeds that of other types |

| Compliance | SAE J1453 and ISO 8434-3 |

These fittings also meet stringent industry standards like SAE J1453 and ISO 8434-3, ensuring safety and performance. Their ability to handle varying fluid types and temperatures makes them a versatile choice for hydraulic systems.

Note: Parker Face Seal fittings are ideal for systems requiring high-pressure capabilities and temperature flexibility. Their compliance with industry standards adds an extra layer of reliability.

Heavy DIN Metric Fittings: Features, Advantages, and Ideal Applications

Heavy DIN Metric fittings are a staple in hydraulic systems across Europe and beyond. These fittings follow the Deutsches Institut für Normung (DIN) standards, ensuring consistency and reliability. Their robust design makes them a go-to choice for high-pressure applications in industries like manufacturing, automotive, and heavy machinery.

One of the standout features of Heavy DIN Metric fittings is their compatibility with metric-sized hoses and tubing. This makes them ideal for systems that require precise measurements and tight tolerances. They also feature a 24-degree cone connection, which provides a secure seal and reduces the risk of leaks. Engineers often choose these fittings for their ability to handle pressures up to 6,000 psi, depending on the size and material.

Advantages of Heavy DIN Metric Fittings:

- Standardization: Adherence to DIN standards ensures compatibility across various systems and manufacturers.

- High Pressure Capability: Suitable for demanding applications, including hydraulic presses and injection molding machines.

- Durability: Made from materials like stainless steel and carbon steel, these fittings resist wear and corrosion.

- Ease of Installation: Their straightforward design simplifies assembly, reducing installation time.

Heavy DIN Metric fittings shine in environments where reliability and precision are critical. For example, they are widely used in construction equipment, where hydraulic systems face constant stress. Their ability to maintain a secure connection under extreme conditions makes them a trusted choice for engineers worldwide.

Tip: When selecting Heavy DIN Metric fittings, always verify the pressure rating and material compatibility to ensure optimal performance.

Grip-Crimp Series Fittings: Features, Advantages, and Ideal Applications

Grip-Crimp Series fittings represent the next generation of hydraulic hose fittings. Designed for high-pressure applications, these fittings combine advanced engineering with user-friendly features. Industries like agriculture, mining, and oil and gas rely on Grip-Crimp fittings for their exceptional performance and reliability.

What sets Grip-Crimp fittings apart is their innovative crimping technology. The fittings use a unique grip mechanism that ensures a secure connection between the hose and fitting. This design minimizes the risk of blowouts, even under extreme pressure. Additionally, the crimping process is quick and straightforward, making these fittings a favorite among technicians.

Key Features of Grip-Crimp Series Fittings:

- Enhanced Grip: The crimping mechanism provides a tight seal, reducing the chance of leaks.

- High Pressure Tolerance: Capable of handling pressures up to 10,000 psi, depending on the hose and fitting combination.

- Corrosion Resistance: Available in materials like stainless steel and plated steel for added durability.

- Versatility: Compatible with a wide range of hydraulic hoses, including braided and spiral designs.

Grip-Crimp fittings excel in applications where safety and efficiency are paramount. For instance, they are often used in offshore drilling rigs, where hydraulic systems must perform flawlessly under harsh conditions. Their ability to withstand high pressures and corrosive environments makes them a reliable choice for critical operations.

Pro Tip: Regularly inspect Grip-Crimp fittings for signs of wear or damage. Proper maintenance can extend their lifespan and ensure system safety.

Choosing the right hydraulic hose fittings is essential for high-pressure systems. The right fittings improve safety, reduce downtime, and enhance overall performance. Operators who take the time to evaluate their system’s needs and consult experts can avoid costly mistakes and ensure long-term reliability.

Advancements in hydraulic technology make 2025 an exciting year for high-pressure applications.

- High-performance polymers like thermoplastic polyurethane (TPU) offer greater durability in extreme conditions.

- Eco-friendly materials reduce environmental impact while meeting sustainability goals.

- Smart sensors enable real-time monitoring of pressure and temperature, boosting efficiency and safety.

By staying informed and leveraging these innovations, businesses can optimize their hydraulic systems for the future.

FAQ

What are the main benefits of using high-quality hydraulic hose fittings?

High-quality fittings improve system safety, reduce leaks, and extend equipment life. They also minimize downtime and maintenance costs. Reliable fittings ensure consistent performance, even under extreme pressure or harsh environmental conditions.

How often should hydraulic hose fittings be inspected?

Inspect fittings every three to six months or during routine maintenance. Look for signs of wear, corrosion, or leaks. Regular checks help prevent unexpected failures and keep systems running smoothly.

Can I reuse hydraulic hose fittings?

Reusable fittings are available, but not all fittings can be reused. Permanent fittings, for example, require crimping and cannot be removed without damage. Always check the fitting type before attempting reuse.

What materials are best for hydraulic hose fittings in corrosive environments?

Stainless steel and brass are excellent choices for corrosive settings. These materials resist rust and chemical damage, ensuring durability and reliability in harsh conditions.

How do I choose the right fitting for my hydraulic system?

Consider the system’s pressure rating, fluid type, and environmental conditions. Match the fitting material to the fluid and operating environment. Consulting manufacturer specifications or an expert ensures the best choice for your application.

Tip: Always verify compatibility between the fitting and the hose to avoid leaks or failures.

Post time: Jun-06-2025