In 2025, the global market for stainless steel fittings is projected to reach a staggering USD 5.09 billion. This growth underlines the importance of leading manufacturers like OmegaOne, M&R Engineering Inc, and Advance Fittings Corp. These companies play a crucial role in the stainless steel fittings industry, supplying essential products like hydraulic hose connectors and Parker hose fittings. Choosing the right supplier can make a significant difference in meeting specific project needs.

Key Takeaways

- The global market for stainless steel fittings is projected to reach USD 5.09 billion by 2025, highlighting the importance of choosing the right supplier.

- Leading manufacturers like OmegaOne and M&R Engineering Inc. offer diverse product ranges, ensuring they meet specific project needs across various industries.

- Quality certifications, such as ISO 9001, are crucial indicators of a manufacturer’s reliability and commitment to high standards.

- Sustainability trends are reshaping the industry, with companies increasingly adopting eco-friendly materials and practices to meet consumer preferences.

- When selecting a supplier, consider their market presence, product offerings, and customer support to ensure a successful project outcome.

Top Manufacturers Overview

Key Players in the Market

The stainless steel fittings market features several key players that stand out due to their specialization and production capabilities. Notable manufacturers include:

- Hikelok: They focus on high-purity stainless steel fittings, catering to industries like food and pharmaceuticals.

- Xinyue Steel Group: This company ranks among China’s largest steel suppliers, producing over 10,000 tons monthly and boasting a strong international presence.

- Tsingshan Holding Group: As the world’s largest stainless steel producer, they ensure raw material stability through vertical integration.

- Tianjin Pipe Corporation (TPCO): Known as China’s largest seamless steel pipe manufacturer, TPCO specializes in seamless pipes and fittings for the oil and gas sectors.

These manufacturers excel in various criteria, including compliance with international standards, production scale, and quality certifications. Their technical expertise and ability to provide comprehensive documentation and support further solidify their positions in the market.

Market Trends Influencing Suppliers

The stainless steel fittings market is on the rise, projected to reach $8.6 billion by 2025, with a compound annual growth rate (CAGR) of 5.2% from 2020. This growth stems from increasing demand in sectors such as oil and gas, water treatment, and chemical processing.

Moreover, sustainability trends are reshaping sourcing decisions. Companies now prefer environmentally-friendly materials and green procurement strategies. This shift not only meets regulatory requirements but also aligns with consumer preferences for sustainable practices. As a result, suppliers must adapt to these changes to remain competitive in the evolving landscape of stainless steel fittings.

Manufacturer 1: OmegaOne

Established Year

OmegaOne has been a significant player in the stainless steel fittings industry since its founding in 1987. Over the years, the company has expanded its manufacturing capabilities and product offerings. This growth has enhanced its reputation as a leading manufacturer in the sector.

| Founding Year | Historical Contributions |

|---|---|

| 1987 | Expanded manufacturing capabilities and product offerings, enhancing reputation as a leading manufacturer in the industry. |

Headquarters

The company is headquartered in Morawica, Poland. This strategic location allows OmegaOne to efficiently manage production and collaborate with suppliers and clients across Europe. The proximity to key markets enhances their adaptability to market needs and quality standards.

| Headquarters Location | Operational Impact |

|---|---|

| Morawica, Poland | Strategic base for production and collaboration with suppliers and clients across Europe, enhancing adaptability to market needs and quality standards. |

Product Offerings

OmegaOne offers a diverse range of products in the stainless steel fittings sector. Their product categories include:

| Product Category | Description |

|---|---|

| Tube Fittings | Includes flare fittings and flareless fittings. |

| Pipe Fittings | Traditional pipe fittings, SAE straight thread fittings, and weld fittings. |

| Metal Hose Weld Fittings | Complements AMFM Braid Band and AMFM Wrapped Band product lines. |

These offerings cater to various industries, ensuring that OmegaOne meets the specific needs of its clients.

Notable Features

What sets OmegaOne apart from other manufacturers? Here are some notable features and innovations:

| Feature/Innovation | Description |

|---|---|

| Product Range | Offers a variety of fittings including AMFM Braid Band, flare fittings, flareless fittings, hose-barb fittings, and weld fittings. |

| Industry Applications | Serves multiple industries such as agriculture, construction, manufacturing, power generation, and transportation. |

| Quality Assurance | Holds ISO 9001:2015 certification, indicating a commitment to quality in manufacturing. |

These features highlight OmegaOne’s commitment to quality and innovation in the stainless steel fittings market.

Notable Features

OmegaOne stands out in the stainless steel fittings market for several reasons. Here are some notable features that make them a preferred choice among customers:

- Diverse Product Range: OmegaOne offers a wide variety of fittings. Their selection includes:

- Flare Fittings: Ideal for high-pressure applications.

- Flareless Fittings: Perfect for quick assembly without special tools.

- Weld Fittings: Designed for permanent connections in piping systems.

Tip: When selecting fittings, consider the specific requirements of your project. OmegaOne’s diverse offerings can cater to various needs.

- Industry Applications: OmegaOne serves multiple sectors, including:

- Agriculture: Providing durable solutions for irrigation systems.

- Manufacturing: Supporting production lines with reliable fittings.

- Power Generation: Ensuring safety and efficiency in energy systems.

| Industry | Application Example |

|---|---|

| Agriculture | Irrigation systems |

| Manufacturing | Production line fittings |

| Power Generation | Safety fittings for energy systems |

- Quality Assurance: OmegaOne prioritizes quality. They hold the ISO 9001:2015 certification, which reflects their commitment to maintaining high manufacturing standards. This certification assures customers that they receive reliable and durable products.

- Customer Support: OmegaOne believes in building strong relationships with clients. They offer:

- Technical Assistance: Expert advice on product selection and installation.

- Custom Solutions: Tailored fittings to meet unique project specifications.

These features highlight OmegaOne’s dedication to quality, innovation, and customer satisfaction in the stainless steel fittings industry. Whether you need standard fittings or custom solutions, OmegaOne has the expertise and products to meet your needs.

Manufacturer 2: M&R Engineering Inc

Established Year

M&R Engineering Inc. has been a key player in the stainless steel fittings industry since its founding in 1973. Originally starting as a davenport screw machine shop, the company has grown significantly over the years. They expanded their capabilities and formed partnerships in precision machining. Notably, M&R Engineering increased its product offerings from 300 to over 1,000 individual part numbers, particularly for aerospace and defense applications. In 2007, they acquired R&B Plastics, further enhancing their manufacturing capabilities.

Headquarters

M&R Engineering Inc. is headquartered in Davenport, Iowa. This central location allows them to efficiently serve clients across the United States. Their strategic position helps streamline logistics and maintain strong relationships with suppliers and customers alike.

Product Offerings

M&R Engineering Inc. specializes in a variety of stainless steel fittings. Their product range includes:

| Product Type | Description |

|---|---|

| Butt-weld pipe fittings | Cold formed fittings for joining pipes |

| Extruded outlets | Outlets for pipe systems |

| Manifolds | Components for distributing fluids |

| Elbows | 90 LR & SR Elbows, 45 LR Elbows, 180 Return Bends |

| Tees | Equal & Reducing Tees |

| Reducers | Concentric & Eccentric Reducers |

| Caps | End Caps |

| Stub ends | Fittings for pipe ends |

| Swage nipples | Fittings for connecting pipes |

| Gaskets | Sealing components for fittings |

| Flanges | Connecting components for pipes |

| Crosses | Fittings for intersecting pipes |

These products cater to various industries, including aerospace, military defense, and healthcare.

M&R Engineering stands out in the industry due to several unique features:

| Feature/Certification | Description |

|---|---|

| Experience | Over 50 years in high-precision machining of metal and plastic parts. |

| Certifications | ISO 9001 and AS9100 certifications, ensuring quality and compliance with industry standards. |

| Services Offered | CNC milling, screw machining, and supply chain integration. |

| Industry Focus | Aerospace, military defense, and healthcare sectors. |

| Business Type | Woman-owned small business with a strong commitment to customer satisfaction and rapid delivery. |

M&R Engineering has successfully built lasting relationships with over 100 satisfied clients, leveraging their technical expertise to deliver exceptional results. Their commitment to quality and customer service makes them a reliable choice for stainless steel fittings.

Notable Features

M&R Engineering Inc. stands out in the stainless steel fittings market for several key reasons. Here are some notable features that make them a preferred choice among customers:

- Extensive Experience: With over 50 years in the industry, M&R Engineering has honed its skills in high-precision machining. Their long-standing presence gives clients confidence in their expertise.

- Quality Certifications: M&R Engineering holds both ISO 9001 and AS9100 certifications. These certifications ensure that they meet rigorous quality standards, making them a reliable partner for industries that demand precision.

- Diverse Product Range: The company offers a wide variety of fittings, including:

- Butt-weld pipe fittings: Ideal for seamless connections.

- Manifolds: Perfect for fluid distribution.

- Elbows and Tees: Essential for changing directions in piping systems.

Tip: When selecting fittings, consider the specific requirements of your project. M&R Engineering’s diverse offerings can cater to various needs.

- Advanced Manufacturing Capabilities: M&R Engineering utilizes state-of-the-art technology for CNC milling and screw machining. This advanced equipment allows them to produce high-quality parts efficiently.

| Feature/Innovation | Description |

|---|---|

| Experience | Over 50 years in high-precision machining of metal and plastic parts. |

| Certifications | ISO 9001 and AS9100 certifications, ensuring quality and compliance with industry standards. |

| Services Offered | CNC milling, screw machining, and supply chain integration. |

| Industry Focus | Aerospace, military defense, and healthcare sectors. |

- Customer-Centric Approach: M&R Engineering prioritizes customer satisfaction. They offer rapid delivery and technical support, ensuring clients receive the assistance they need.

- Woman-Owned Business: As a woman-owned small business, M&R Engineering promotes diversity in the industry. This commitment to inclusivity resonates with many clients who value supporting diverse suppliers.

These features highlight M&R Engineering’s dedication to quality, innovation, and customer service in the stainless steel fittings industry. Whether you need standard fittings or specialized solutions, M&R Engineering has the expertise and products to meet your needs.

Manufacturer 3: Advance Fittings Corp

Established Year

Advance Fittings Corp has been a significant player in the stainless steel fittings market since its establishment in 1995. Over the years, the company has built a strong reputation for delivering high-quality products that meet the needs of various industries.

Headquarters

Advance Fittings Corp is located in Elkhorn, Wisconsin. This strategic location offers several advantages:

- Proximity to key markets allows for efficient distribution.

- Access to local manufacturing capabilities enhances production efficiency.

- The location supports strong relationships with suppliers and customers.

These factors contribute to the company’s ability to respond quickly to market demands.

Product Offerings

Advance Fittings Corp specializes in a wide range of stainless steel fittings. Their product offerings include:

| Product Type | Description |

|---|---|

| Tube Fittings | Includes various configurations for different applications. |

| Pipe Fittings | Offers a variety of sizes and types for seamless connections. |

| Specialty Fittings | Custom solutions tailored to specific project requirements. |

What sets Advance Fittings Corp apart from other manufacturers? Here are some key differentiators:

| Key Differentiator | Description |

|---|---|

| High-Quality Products | Recognized for high-quality stainless steel fittings. |

| Strong Industry Ranking | Ranked highly in directories like Metoree, indicating a solid reputation. |

| Domestic Manufacturing | Commitment to manufacturing excellence within the US, ensuring quality. |

| Supply Chain Reliability | Advantages in supply chain reliability due to domestic production. |

| Adherence to US Standards | Compliance with US standards enhances trust and quality assurance. |

| Proven Track Record | High ranking suggests customer satisfaction and product performance. |

| Ideal for Domestic Sourcing Projects | Excellent choice for projects prioritizing domestic sourcing and quality. |

Advance Fittings Corp’s commitment to quality and reliability makes them a preferred choice for many customers. Their focus on domestic manufacturing ensures that they meet stringent standards while supporting local economies.

Notable Features

Advance Fittings Corp stands out in the stainless steel fittings market for several key reasons. Here are some notable features that make them a preferred choice among customers:

- High-Quality Products: Advance Fittings Corp is known for its commitment to quality. They ensure that every fitting meets strict industry standards. This dedication to quality helps build trust with clients.

- Strong Industry Ranking: The company consistently ranks highly in directories like Metoree. This recognition reflects their solid reputation and customer satisfaction.

- Domestic Manufacturing: Advance Fittings Corp focuses on manufacturing within the United States. This approach not only supports local economies but also guarantees adherence to US standards. Customers appreciate the reliability that comes with domestic production.

- Supply Chain Reliability: By producing fittings domestically, Advance Fittings Corp enhances supply chain reliability. Clients can count on timely deliveries and consistent product availability.

- Proven Track Record: The company has a history of successful projects and satisfied customers. Their high ranking in the industry suggests that they deliver on their promises.

Tip: When choosing a supplier, consider their track record. A proven history of quality and reliability can save you time and money in the long run.

| Feature | Description |

|---|---|

| High-Quality Products | Commitment to strict industry standards ensures reliable fittings. |

| Strong Industry Ranking | Consistently recognized in directories, indicating customer satisfaction. |

| Domestic Manufacturing | Focus on US production supports local economies and ensures quality. |

| Supply Chain Reliability | Timely deliveries and consistent availability enhance customer trust. |

| Proven Track Record | History of successful projects builds confidence in their offerings. |

These features highlight Advance Fittings Corp’s dedication to quality, reliability, and customer satisfaction. Whether you need standard fittings or specialized solutions, they have the expertise and products to meet your needs.

Manufacturer 4: Stainless Fittings Group

Established Year

Stainless Fittings Group has been a key player in the stainless steel fittings market since its establishment in 2001. Over the years, the company has built a solid reputation for providing high-quality products tailored to meet the needs of various industries.

Headquarters

The company is headquartered in Fort Worth, Texas. This location plays a crucial role in its operations, allowing for efficient distribution and strong connections with clients. The strategic position also enables Stainless Fittings Group to serve the beverage industry effectively, particularly in providing stainless steel fittings for beverage dispensing systems.

| Headquarters | Primary Market Served |

|---|---|

| Fort Worth, Texas | Beverage industry (stainless steel fittings for beverage dispensing systems) |

Product Offerings

Stainless Fittings Group specializes in a diverse range of stainless steel fittings. Their product offerings include:

| Product Type | Material | Size Range |

|---|---|---|

| Stub Ends | Stainless Steel | 0.5″-24″ |

| Carbon Steel | 0.5″-24″ | |

| Alloy 20 | 0.5″-12″ | |

| Aluminum | 0.5″-8″ | |

| Plate Flanges | Stainless Steel | 0.5″-26″ |

| Angle Face Rings | 0.5″-12″ | |

| Concentric Reducers | Stainless/Carbon | 0.5″-12″ |

These products cater to various applications, especially in the beverage sector. The company’s commitment to quality ensures that their fittings meet industry standards, providing reliability and durability for their customers.

Stainless Fittings Group stands out due to its focus on customer satisfaction and product innovation. They continuously strive to improve their offerings, ensuring they meet the evolving needs of the market.

Tip: When selecting stainless steel fittings, consider the specific requirements of your project. Stainless Fittings Group’s diverse range can help you find the right solution.

Notable Features

Stainless Fittings Group stands out in the stainless steel fittings market for several compelling reasons. Here are some notable features that make them a preferred choice among customers:

- Customer-Centric Approach: Stainless Fittings Group prioritizes customer satisfaction. They actively seek feedback and adapt their products based on client needs. This commitment fosters strong relationships and ensures that customers feel valued.

- Innovative Product Development: The company continuously invests in research and development. They strive to create new products that meet the evolving demands of various industries. This focus on innovation helps them stay ahead of competitors.

- Quality Assurance: Stainless Fittings Group emphasizes quality in every product. They adhere to strict industry standards, ensuring that their fittings are reliable and durable. Customers can trust that they receive top-notch products every time.

Tip: When choosing fittings, always consider the manufacturer’s commitment to quality. It can save you time and money in the long run!

- Diverse Product Range: Their extensive selection of fittings caters to various applications. Whether you need fittings for beverage dispensing or industrial use, Stainless Fittings Group has you covered. Here’s a quick look at their offerings:

| Product Type | Description |

|---|---|

| Stub Ends | Available in multiple materials and sizes. |

| Plate Flanges | Ideal for connecting pipes in various systems. |

| Concentric Reducers | Perfect for transitioning between pipe sizes. |

- Strategic Location: Being headquartered in Fort Worth, Texas, allows for efficient distribution. This location helps them serve the beverage industry effectively, ensuring timely deliveries.

- Sustainability Practices: Stainless Fittings Group is committed to sustainable practices. They focus on minimizing waste and using eco-friendly materials whenever possible. This dedication to sustainability resonates with environmentally-conscious customers.

These features highlight why Stainless Fittings Group is a trusted name in the stainless steel fittings industry. Their commitment to quality, innovation, and customer satisfaction makes them a go-to choice for many businesses.

Manufacturer 5: Jay Steel Corporation

Established Year

Jay Steel Corporation has been a significant player in the stainless steel fittings market since its establishment in 1961. Over the years, the company has solidified its position as a leading manufacturer in the construction and manufacturing industries.

| Establishment Year | Industry Standing |

|---|---|

| 1961 | Leading player in manufacturing and construction industries |

Headquarters

The company is headquartered in Mumbai, India. This prime location allows Jay Steel Corporation to efficiently serve both domestic and international markets. Their strategic base enhances logistics and fosters strong relationships with clients and suppliers.

| Headquarters Location | Operational Impact |

|---|---|

| Mumbai, India | Efficient service to domestic and international markets, enhancing logistics and client relationships |

Product Offerings

Jay Steel Corporation specializes in a wide range of stainless steel fittings. Their product offerings include:

| Product Type | Link |

|---|---|

| Stainless Steel Tube Fittings | View Here |

| Duplex/Super Duplex Steel Tube Fittings | View Here |

| Titanium Tube Fittings | View Here |

| Alloy 20 Tube Fittings | View Here |

| Monel Alloy 400 Tube Fittings | View Here |

| Carbon Steel Tube Fittings | View Here |

| Inconel Alloy 600/625 Tube Fittings | View Here |

| Brass Tube Fittings | View Here |

Jay Steel Corporation stands out in the market due to several unique selling points:

| Unique Selling Point | Description |

|---|---|

| Commitment to Quality | Products undergo rigorous testing and adhere to international quality standards for superior performance and longevity. |

| Customization Options | Tailored solutions to meet specific project requirements, including size, grade, and form. |

| Strong Global Presence | Established presence in the global market, enhancing reliability and trust among clients. |

With a commitment to quality and customer satisfaction, Jay Steel Corporation continues to be a preferred choice for stainless steel fittings across various industries. Their diverse product range and dedication to meeting client needs make them a reliable partner for any project.

Notable Features

Jay Steel Corporation stands out in the stainless steel fittings market for several compelling reasons. Here are some notable features that make them a preferred choice among customers:

- Commitment to Quality: Jay Steel Corporation prioritizes quality in every product they manufacture. They conduct rigorous testing to ensure that their fittings meet international quality standards. This dedication guarantees superior performance and longevity, giving customers peace of mind.

- Customization Options: The company offers tailored solutions to meet specific project requirements. Whether clients need unique sizes, grades, or forms, Jay Steel Corporation can accommodate those needs. This flexibility allows them to serve a diverse range of industries effectively.

Tip: When selecting fittings, consider whether the manufacturer offers customization options. Tailored solutions can significantly enhance project outcomes.

- Strong Global Presence: With an established presence in the global market, Jay Steel Corporation enhances reliability and trust among clients. Their ability to serve both domestic and international markets allows them to cater to a wide array of customer needs.

| Unique Selling Point | Description |

|---|---|

| Commitment to Quality | Rigorous testing and adherence to international standards ensure superior performance. |

| Customization Options | Tailored solutions for specific project requirements, including size, grade, and form. |

| Strong Global Presence | Established in the global market, enhancing reliability and trust among clients. |

- Diverse Product Range: Jay Steel Corporation provides a wide variety of stainless steel fittings. Their offerings include tube fittings, duplex steel fittings, and specialty alloys. This extensive selection ensures that clients find the right products for their specific applications.

- Customer-Centric Approach: The company actively seeks feedback from clients and adapts its products based on their needs. This commitment to customer satisfaction fosters strong relationships and ensures that clients feel valued.

These features highlight why Jay Steel Corporation is a trusted name in the stainless steel fittings industry. Their commitment to quality, innovation, and customer satisfaction makes them a go-to choice for many businesses.

Manufacturer 6: Mid-America Fitting Inc.

Established Year

Mid-America Fitting Inc. has been a prominent player in the stainless steel fittings market since its founding in 1985. Over the years, the company has developed a strong reputation for producing high-quality fittings that cater to various industries.

Headquarters

The company is headquartered in Shawnee Mission, Kansas. This location plays a vital role in its operations, allowing for efficient distribution and strong connections with clients. Mid-America Fitting Inc. serves a wide range of applications and provides custom components for original equipment manufacturers (OEMs) and industrial distributors.

| Headquarters | Market Reach |

|---|---|

| Shawnee Mission, Kansas | Various applications and custom components for OEMs and industrial distributors. |

Product Offerings

Mid-America Fitting Inc. specializes in a diverse range of stainless steel fittings. Their product offerings include:

- Pipe Fittings: These fittings are essential for connecting pipes in various systems.

- Tube Fittings: Designed for high-pressure applications, these fittings ensure secure connections.

- Custom Components: The company excels in manufacturing tailored solutions to meet specific project requirements.

What sets Mid-America Fitting Inc. apart from other manufacturers? Here are some key distinguishing features:

| Feature | Description |

|---|---|

| Extensive Manufacturing | Over 70 screw machines enable production of over 5,000 fitting products for various industries. |

| Customer Service | High product in-stock levels and commitment to customer satisfaction. |

| Environmental Responsibility | Commitment to industry-leading environmental best practices. |

Additionally, Mid-America Fitting Inc. has received recognition for its excellence in business practices. They were honored as a “Top Ten” small business by the Kansas City Chamber of Commerce. This acknowledgment highlights their ability to manufacture custom parts for a wide range of applications, enhancing their versatility in the market.

Tip: When selecting a supplier for stainless steel fittings, consider their ability to provide custom solutions. This flexibility can significantly enhance project outcomes.

These features underscore Mid-America Fitting Inc.’s commitment to quality, customer satisfaction, and environmental responsibility. Their extensive product range and dedication to meeting client needs make them a reliable partner for any project.

Notable Features

When it comes to stainless steel fittings, each manufacturer brings something unique to the table. Here are some notable features that set them apart:

- OmegaOne:

- Diverse Product Range: They offer a wide variety of fittings, including flare and weld fittings. This variety ensures that customers can find exactly what they need for their projects.

- Quality Assurance: OmegaOne holds the ISO 9001:2015 certification, which guarantees high manufacturing standards. Customers can trust that they receive durable and reliable products.

Tip: Always check for quality certifications when selecting fittings. It can save you from future headaches!

- M&R Engineering Inc.:

- Extensive Experience: With over 50 years in the industry, they have honed their skills in precision machining. This experience gives clients confidence in their products.

- Certifications: M&R Engineering boasts both ISO 9001 and AS9100 certifications. These certifications ensure they meet strict quality standards, especially for aerospace and defense applications.

| Feature | Description |

|---|---|

| Experience | Over 50 years in high-precision machining. |

| Certifications | ISO 9001 and AS9100 certifications. |

- Advance Fittings Corp:

- Domestic Manufacturing: They focus on producing fittings within the United States. This commitment supports local economies and ensures adherence to US standards.

- Strong Industry Ranking: Advance Fittings consistently ranks highly in industry directories, reflecting their solid reputation and customer satisfaction.

Note: Choosing a manufacturer with a strong industry ranking can lead to better product quality and service.

- Stainless Fittings Group:

- Customer-Centric Approach: They prioritize customer feedback and adapt their products accordingly. This focus helps them build strong relationships with clients.

- Innovative Product Development: The company invests in research and development to create new products that meet evolving market demands.

- Jay Steel Corporation:

- Commitment to Quality: They conduct rigorous testing to ensure their fittings meet international standards. This dedication guarantees superior performance and longevity.

- Customization Options: Jay Steel offers tailored solutions to meet specific project requirements, making them versatile for various applications.

| Unique Selling Point | Description |

|---|---|

| Commitment to Quality | Rigorous testing ensures superior performance. |

| Customization Options | Tailored solutions for specific needs. |

- Mid-America Fitting Inc.:

- Extensive Manufacturing Capabilities: With over 70 screw machines, they produce a vast range of fittings. This capability allows them to cater to various industries efficiently.

- Environmental Responsibility: They follow industry-leading environmental practices, showing their commitment to sustainability.

These notable features highlight why these manufacturers are leaders in the stainless steel fittings market. Their dedication to quality, innovation, and customer satisfaction makes them reliable partners for any project.

Manufacturer 7: Pennsylvania Steel Company

Established Year

Pennsylvania Steel Company has been a significant player in the stainless steel fittings market since its founding in 1970. Over the years, the company has built a strong reputation for providing high-quality products that meet the needs of various industries. Their long-standing presence in the market showcases their commitment to excellence and innovation.

Headquarters

The company is headquartered in York, Pennsylvania. This strategic location allows Pennsylvania Steel Company to efficiently serve clients across the United States. Being in the heart of the manufacturing hub, they can easily access suppliers and maintain strong relationships with customers. This proximity enhances their ability to respond quickly to market demands.

Product Offerings

Pennsylvania Steel Company specializes in a wide range of stainless steel fittings. Their product offerings include:

| Product Type | Description |

|---|---|

| Pipe Fittings | Essential for connecting pipes in various systems. |

| Tube Fittings | Designed for high-pressure applications, ensuring secure connections. |

| Flanges | Used to connect pipes, valves, and other equipment. |

| Specialty Fittings | Custom solutions tailored to specific project requirements. |

Their diverse product range caters to various industries, including construction, manufacturing, and energy. Pennsylvania Steel Company prides itself on delivering reliable and durable products that meet stringent industry standards.

Tip: When selecting stainless steel fittings, consider the specific requirements of your project. Pennsylvania Steel Company’s extensive offerings can help you find the right solution.

With a focus on quality and customer satisfaction, Pennsylvania Steel Company continues to be a trusted name in the stainless steel fittings industry. Their commitment to innovation and excellence makes them a preferred choice for many businesses.

Notable Features

Pennsylvania Steel Company stands out in the stainless steel fittings market for several key reasons. Here are some notable features that make them a preferred choice among customers:

- Commitment to Quality: Pennsylvania Steel Company places a strong emphasis on quality. They conduct rigorous testing on their products to ensure they meet industry standards. This dedication guarantees that customers receive reliable and durable fittings.

- Diverse Product Range: The company offers a wide variety of stainless steel fittings. Their product lineup includes:

Product Type Description Pipe Fittings Essential for connecting pipes in various systems. Tube Fittings Designed for high-pressure applications, ensuring secure connections. Flanges Used to connect pipes, valves, and other equipment. Specialty Fittings Custom solutions tailored to specific project requirements.

Tip: When selecting fittings, consider the specific requirements of your project. Pennsylvania Steel Company’s extensive offerings can help you find the right solution.

- Strong Customer Relationships: Pennsylvania Steel Company values its customers. They actively seek feedback and adapt their products based on client needs. This approach fosters strong relationships and ensures that customers feel valued.

- Strategic Location: Being headquartered in York, Pennsylvania, allows for efficient distribution. This location helps them serve clients across the United States quickly. Their proximity to suppliers also enhances their ability to respond to market demands.

- Innovative Solutions: The company invests in research and development. They continuously strive to create new products that meet the evolving demands of various industries. This focus on innovation helps them stay ahead of competitors.

These features highlight why Pennsylvania Steel Company is a trusted name in the stainless steel fittings industry. Their commitment to quality, innovation, and customer satisfaction makes them a go-to choice for many businesses.

Comparative Analysis of Stainless Steel Fittings Manufacturers

When evaluating the leading manufacturers of stainless steel fittings, it’s essential to consider their market presence, distribution channels, and global reach. These factors significantly influence their ability to serve customers effectively.

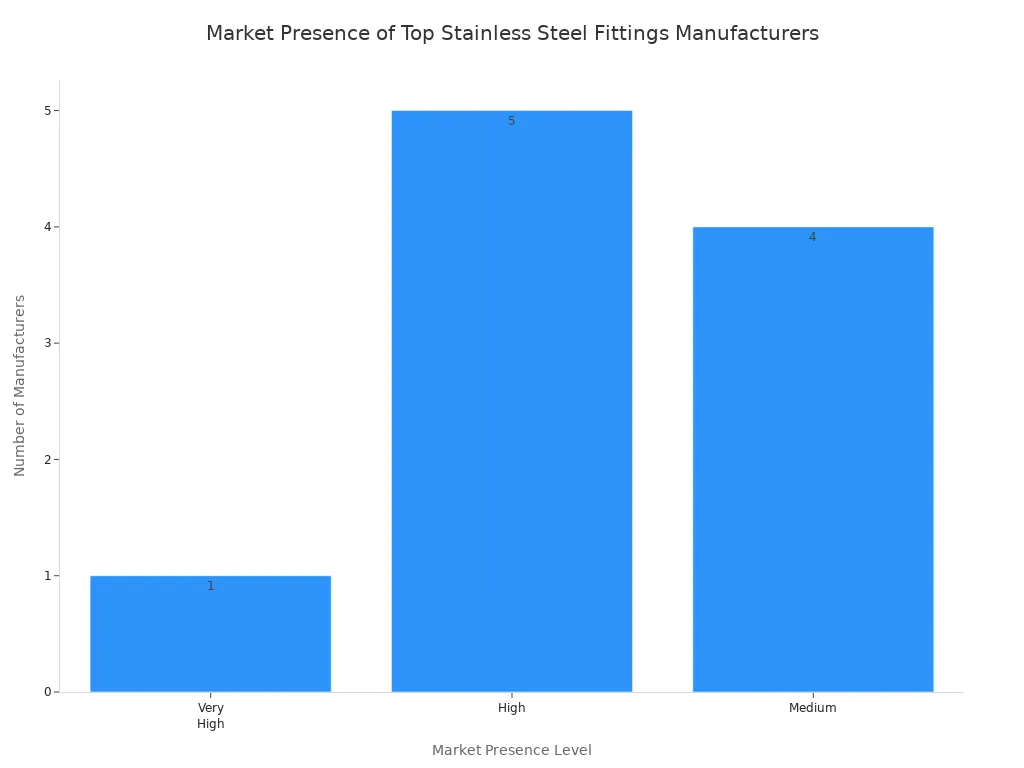

Market Presence

The market presence of a manufacturer reflects its influence and reputation in the industry. Here’s a comparison of several key players:

| Manufacturer | Market Presence | Distribution Channels | Strategy Overview |

|---|---|---|---|

| Acerinox | High | N/A | Marketing, Product, Channel |

| Baoshan Iron & Steel Co., Ltd. | High | N/A | N/A |

| AK Steel Corporation | Medium | N/A | N/A |

| Jindal Stainless Group | High | N/A | N/A |

| Outokumpu Oyj | High | N/A | N/A |

| Aperam | Medium | N/A | N/A |

| Nippon Steel | High | N/A | N/A |

| ArcelorMittal SA | Very High | N/A | N/A |

| Hitachi Metals Neomaterial, Ltd | Medium | N/A | N/A |

| Toho International Inc. | Medium | N/A | N/A |

Distribution Channels

Distribution channels play a crucial role in how manufacturers deliver their products to customers. Many leading companies utilize a mix of direct sales, online platforms, and partnerships with distributors. This strategy helps them reach a broader audience and ensures timely delivery of stainless steel fittings.

Global Reach

The global reach of these manufacturers varies significantly. Companies like ArcelorMittal and Nippon Steel have established a strong international presence, allowing them to cater to diverse markets. Others, such as AK Steel, focus more on regional markets, which can limit their global influence.

Understanding these dynamics helps businesses choose the right supplier for their specific needs. A manufacturer with a strong market presence and efficient distribution channels can provide better service and product availability.

In summary, the leading manufacturers of stainless steel fittings, such as OmegaOne, M&R Engineering Inc., and Advance Fittings Corp, play a vital role in various industries. Their commitment to quality and reliability ensures that customers receive durable products. When selecting a supplier, consider your specific needs. A good fit can make all the difference in your project’s success. Remember, the right supplier not only provides quality fittings but also supports your goals.

Tip: Always check for certifications and customer reviews to ensure you choose a reliable supplier.

FAQ

What are stainless steel fittings used for?

Stainless steel fittings connect pipes and tubes in various applications. They are essential in industries like plumbing, oil and gas, and food processing, ensuring secure and leak-free connections.

How do I choose the right stainless steel fitting?

Consider factors like the application, pressure requirements, and compatibility with existing materials. Consulting with suppliers can help identify the best fitting for specific project needs.

Are stainless steel fittings resistant to corrosion?

Yes, stainless steel fittings are highly resistant to corrosion. Their durability makes them ideal for harsh environments, including marine and chemical applications.

What certifications should I look for in manufacturers?

Look for ISO certifications, such as ISO 9001, which indicate quality management standards. Certifications ensure that manufacturers adhere to industry regulations and produce reliable products.

Can I customize stainless steel fittings?

Many manufacturers offer customization options. Clients can request specific sizes, shapes, or materials to meet unique project requirements, enhancing the fitting’s effectiveness in their applications.

Post time: Sep-18-2025