Thermoplastic hose ends play a crucial role in countless industries, including those that utilize paint sprayer hose and fittings. They’re the unsung heroes of efficient fluid transfer systems, especially in high-demand sectors like construction, agriculture, and manufacturing. Why are they so essential? For starters, they’re lightweight, durable, and chemically resistant—qualities that make them a superior choice over traditional rubber hoses. Industries also favor them for their environmental benefits and flexibility.

Recent trends show a shift toward thermoplastic options due to advancements in materials and designs. Manufacturers now offer specialized solutions for high-pressure applications and even healthcare uses. Whether it’s paint sprayer hose fittings or hydraulic systems, these thermoplastic hose ends help businesses operate more efficiently and sustainably. Comparing offerings from industry leaders ensures users get the best fit for their unique needs, particularly when it comes to paint sprayer hose and fittings.

Key Takeaways

- Thermoplastic hose ends are light and strong, perfect for tough jobs like building and farming.

- They resist chemicals well, keeping fluids safe in harsh places.

- Picking the right hose ends can make systems work better and cost less to fix, saving money over time.

- Companies can customize hose ends to fit their specific needs.

- Many hose ends can be recycled, helping the environment and cutting down waste.

Overview of Thermoplastic Hose Ends

What Are Thermoplastic Hose Ends?

Thermoplastic hose ends are specialized components designed to connect hoses to various systems or equipment. They ensure secure and leak-free connections, which are vital for fluid transfer in industrial and commercial applications. Technically, a hose consists of three parts: a tube, reinforcement, and a cover. If reinforcement is absent, the product is classified as tubing rather than a hose. This distinction matters because hoses are built for durability and high-pressure environments, while tubing is suited for simpler tasks.

These hose ends are made from thermoplastic materials, which are lightweight, flexible, and resistant to chemicals. Their design caters to industries that demand reliable performance under challenging conditions, such as extreme temperatures or corrosive environments.

Key Features and Benefits of Thermoplastic Hose Ends

Thermoplastic hose ends offer several advantages that make them a preferred choice across industries:

- Lightweight Construction: Easier to handle and install compared to metal alternatives.

- Chemical Resistance: Ideal for transferring fluids that may corrode other materials.

- Durability: Withstand wear and tear in high-pressure applications.

- Flexibility: Adaptable to tight spaces and complex system layouts.

- Environmental Sustainability: Many thermoplastic materials are recyclable, aligning with green initiatives.

These features contribute to their growing popularity in sectors like automotive, manufacturing, and agriculture.

Tip: Choosing the right thermoplastic hose ends can improve system efficiency and reduce maintenance costs over time.

Common Applications Across Industries

Thermoplastic hose ends are versatile and find use in a wide range of industries. Here’s a snapshot of their applications:

| Application Area | Description |

|---|---|

| Shipbuilding | Essential for fluid transfer in ship systems. |

| Paper Machine Construction | Handle specific fluids in paper machine setups. |

| Hydraulics | Provide reliable connections for hydraulic systems. |

| Paint Shops | Ensure safe fluid transfer in paint applications. |

| Offshore Industry | Operate effectively in harsh offshore environments. |

| Food Industry | Meet stringent food safety standards. |

| Water Management | Support systems for managing water resources. |

The demand for thermoplastic hose ends continues to rise. The global market for hydraulic thermoplastic hoses is projected to exceed $3 billion by 2033, driven by advancements in manufacturing technologies and the need for lightweight, durable materials. In the U.S., the market is expected to grow at a compound annual growth rate of 5.4% from 2026 to 2033, reflecting their increasing importance in industries like automotive and industrial machinery.

Note: Selecting the right hose ends tailored to specific industry needs ensures optimal performance and system reliability.

Thermoplastic Hose Ends by Parker Parflex Division

Product Range and Key Offerings

Parker Parflex Division offers a wide range of thermoplastic hose ends designed for medium-pressure hydraulic applications. Their 594TJ series stands out for its durability and performance. These hose ends are built with TOUGHJACKET™, an abrasion-resistant cover that ensures longevity even in demanding environments. They also feature a four-spiral wire hose performance in a high-tensile two-wire braid construction, making them lighter and more flexible than traditional rubber hoses.

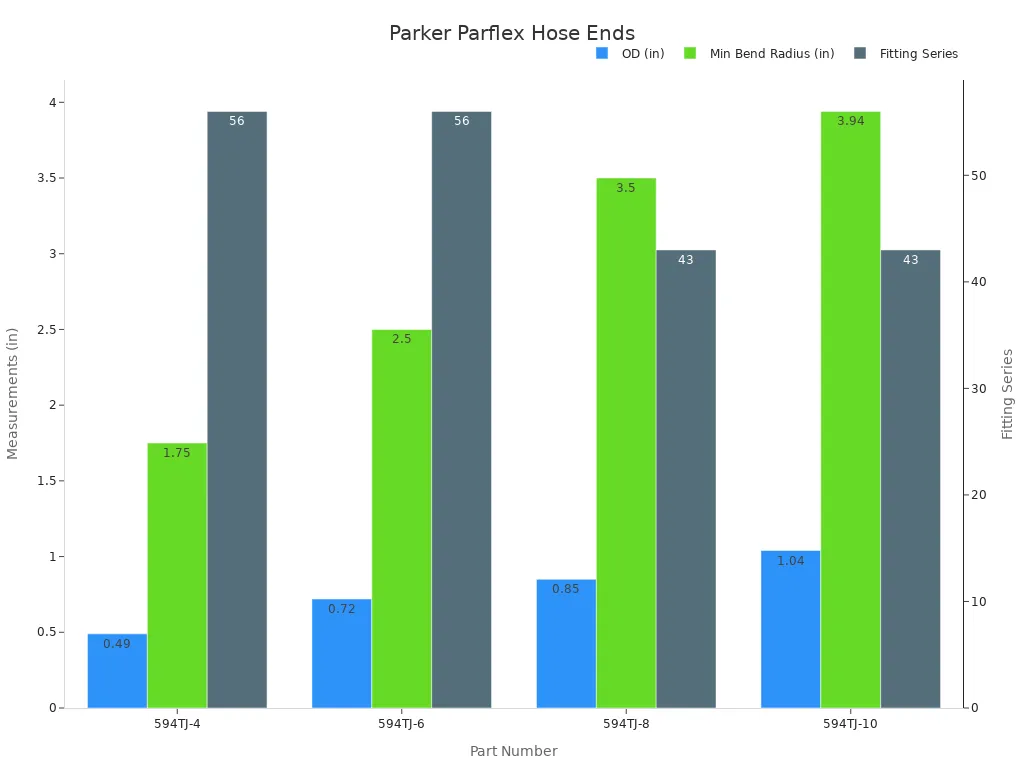

Here’s a quick look at the product specifications for the 594TJ series:

| Part # | ID (in) | OD (in) | Working Pressure (psi) | Min Bend Radius (in) | Permanent Fitting Series |

|---|---|---|---|---|---|

| 594TJ-4 | 1/4 | 0.49 | 4061 | 1.75 | 56 |

| 594TJ-6 | 3/8 | 0.72 | 4061 | 2.50 | 56 |

| 594TJ-8 | 1/2 | 0.85 | 4061 | 3.50 | 43 |

| 594TJ-10 | 5/8 | 1.04 | 4061 | 3.94 | 43 |

These hose ends also offer consistent long lengths, low length change under pressure, and superior bend radius.

Technical Specifications

The 594TJ series thermoplastic hose ends are designed to meet or exceed SAE 100R19 standards. They are MSHA accepted, ensuring safety and reliability in various applications. With a constant working pressure of 4,000 psi, these hose ends deliver exceptional performance. Their lightweight design makes them easier to handle, while their excellent flexibility allows them to adapt to tight spaces.

The TOUGHJACKET™ cover provides abrasion resistance, making these hose ends ideal for harsh environments. Additionally, their low length change under pressure ensures consistent performance, even in high-pressure systems.

Applications and Use Cases

Parker Parflex Division’s thermoplastic hose ends are versatile and suitable for a variety of industries. Common applications include:

- Agricultural Equipment: Reliable fluid transfer for tractors and other machinery.

- Construction Equipment: Durable connections for hydraulic systems in heavy machinery.

- Lubricating Oils: Safe and efficient transfer of oils in industrial settings.

- Transportation: Ideal for hydraulic systems in trucks and other vehicles.

These hose ends are also used in other medium-pressure hydraulic applications, offering a dependable solution for businesses seeking high performance and durability.

Tip: Choosing Parker Parflex Division’s thermoplastic hose ends can help reduce maintenance costs and improve system efficiency over time.

Advantages

Parker Parflex Division’s thermoplastic hose ends come with several standout benefits that make them a top choice for many industries:

- Lightweight Design: These hose ends are much lighter than traditional rubber or metal options. This makes them easier to handle during installation and reduces strain on equipment.

- Abrasion Resistance: The TOUGHJACKET™ cover provides exceptional durability, even in environments where wear and tear are common.

- Flexibility: Their design allows them to bend easily, making them perfect for tight spaces or complex hydraulic systems.

- High Pressure Performance: With a constant working pressure of 4,000 psi, they deliver reliable performance in demanding applications.

- Low Maintenance: Their resistance to chemicals and abrasion means fewer repairs and replacements, saving time and money.

- Environmental Benefits: Many of these hose ends are recyclable, aligning with sustainability goals.

Tip: If your system operates in harsh conditions, these hose ends can help extend the lifespan of your equipment while reducing downtime.

Their combination of durability, flexibility, and eco-friendliness makes them a smart investment for industries like agriculture, construction, and transportation.

Disadvantages

While Parker Parflex Division’s thermoplastic hose ends offer many advantages, they do have a few limitations:

- Higher Initial Cost: Compared to some alternatives, these hose ends may have a higher upfront price. However, their durability often offsets this over time.

- Limited Temperature Range: Although they perform well in most conditions, extreme heat or cold may impact their performance.

- Specialized Applications: These hose ends are designed for specific uses. They may not be the best fit for low-pressure or non-industrial systems.

Note: Understanding your system’s requirements is key. Choosing the wrong hose ends could lead to inefficiencies or even system failures.

Despite these drawbacks, the benefits often outweigh the limitations for businesses that prioritize long-term performance and reliability.

Thermoplastic Hose Ends by Dyna Flex

Product Range and Key Offerings

Dyna Flex has built a reputation for delivering high-quality thermoplastic hose ends that cater to a variety of industries. Their product range includes options for both low- and high-pressure applications, ensuring versatility. These hose ends are designed to handle demanding environments, making them a reliable choice for industries like agriculture, construction, and manufacturing.

One standout feature of Dyna Flex’s offerings is their focus on durability. Their hose ends are crafted with materials that resist wear and tear, even in harsh conditions. This makes them ideal for systems that require consistent performance over time. Additionally, Dyna Flex provides customizable solutions, allowing businesses to tailor hose ends to their specific needs.

Tip: If you’re looking for hose ends that combine durability with flexibility, Dyna Flex’s range is worth exploring.

Technical Specifications

Dyna Flex thermoplastic hose ends are engineered to meet rigorous performance standards. Here’s a breakdown of their key specifications:

| Specification | Value |

|---|---|

| Max Operating Pressure | 4000 PSI |

| Min Burst Pressure | 10000 PSI |

| Temperature Range | -40ºF to 122ºF |

| Min Bend Radius | 2 inches |

| Cover Material | Polyether-urethane |

| Inner Core Material | Seamless polyester tube |

| Reinforcement | High tensile synthetic fiber (one- and two-braid) |

These specifications highlight the strength and adaptability of Dyna Flex hose ends. The polyether-urethane cover ensures excellent abrasion resistance, while the seamless polyester tube provides a smooth inner surface for efficient fluid transfer. With a minimum bend radius of just 2 inches, these hose ends are perfect for tight spaces.

Applications and Use Cases

Dyna Flex thermoplastic hose ends are versatile and find applications across multiple industries. Here are some common use cases:

- Agriculture: Ideal for irrigation systems and machinery that require durable fluid connections.

- Construction: Perfect for hydraulic systems in heavy equipment like excavators and loaders.

- Manufacturing: Reliable for transferring lubricants and other fluids in industrial setups.

- Transportation: Suitable for hydraulic systems in trucks and other vehicles.

Their ability to perform under high pressure and in extreme temperatures makes them a go-to choice for businesses seeking reliability and efficiency.

Note: Choosing the right thermoplastic hose ends can significantly improve system performance and reduce downtime.

Advantages

Dyna Flex thermoplastic hose ends offer several benefits that make them a reliable choice for industrial applications:

- Durability: These hose ends are built to last. Their abrasion-resistant polyether-urethane cover ensures they can handle tough environments without wearing out quickly.

- Flexibility: With a minimum bend radius of just 2 inches, they fit into tight spaces effortlessly. This makes them ideal for complex hydraulic systems.

- High Pressure Capability: They perform exceptionally well under pressure, with a maximum operating pressure of 4,000 PSI and a burst pressure of 10,000 PSI.

- Temperature Resistance: Designed to operate in temperatures as low as -40ºF, they’re perfect for cold climates or refrigerated systems.

- Customizable Options: Dyna Flex offers tailored solutions, allowing businesses to adapt hose ends to their specific needs.

Tip: For industries like agriculture and construction, these hose ends can reduce downtime and improve system efficiency.

Their combination of strength, adaptability, and customization makes them a smart investment for businesses seeking reliable fluid transfer solutions.

Disadvantages

While Dyna Flex thermoplastic hose ends shine in many areas, they do have a few drawbacks:

- Limited Temperature Range: Although they perform well in cold conditions, their upper limit of 122ºF may not suit systems exposed to extreme heat.

- Higher Initial Cost: These hose ends may cost more upfront compared to some alternatives. However, their durability often offsets this over time.

- Specialized Applications: They’re designed for specific industries. Businesses with low-pressure or non-industrial systems might find them unnecessary.

Note: Understanding your system’s requirements is crucial. Choosing the wrong hose ends could lead to inefficiencies or even system failures.

Despite these limitations, Dyna Flex hose ends remain a top choice for industries that prioritize performance and reliability.

Thermoplastic Hose Ends by Eaton

Product Range and Key Offerings

Eaton offers a diverse selection of thermoplastic hose ends designed to meet the needs of various industries. Their products are known for their durability and high performance, making them a reliable choice for demanding applications. Eaton’s thermoplastic hose ends are built with advanced materials like polyurethane and nylon, ensuring resistance to abrasion and chemicals. These features make them suitable for both standard and high-pressure systems.

One standout feature of Eaton’s range is its focus on safety and compliance. Many of their hose ends meet SAE 100R8 certification standards, ensuring they perform reliably under challenging conditions. Eaton also provides options with perforated covers, which enhance flexibility and reduce weight. This makes their hose ends easier to install and maintain, even in tight spaces.

Tip: For industries requiring long-lasting and efficient fluid transfer solutions, Eaton’s thermoplastic hose ends are worth considering.

Technical Specifications

Eaton’s thermoplastic hose ends are engineered to deliver exceptional performance. Here’s a detailed look at their specifications:

| Specification | Value |

|---|---|

| Abrasion Resistance | 28 |

| Alternate Part Number | 3800-02-250BX |

| Certifications | SAE 100R8 |

| Color | Black |

| Conductivity | 30 |

| Construction | 1 Ply Braid |

| Cover Material | Polyurethane |

| Cover Style | Perforated |

| Dash Size | -2 |

| Brand | Danfoss Power Solutions |

| Pack Size | 12.00 FT |

| Features | Highly abrasion resistant cover |

| Impulse Cycle Life | 200000 cycle |

| Minimum Bend Radius | 0.81 |

| Minimum Working Temperature | -40 |

| Product Weight | 2.16 lbs |

| Tube Material | Nylon |

These specifications highlight Eaton’s commitment to quality and innovation. The highly abrasion-resistant cover and impressive impulse cycle life make these hose ends ideal for heavy-duty applications.

Applications and Use Cases

Eaton’s thermoplastic hose ends are versatile and find applications across multiple industries. They are commonly used in:

- Hydraulics: Perfect for high-pressure hydraulic systems in construction and agriculture.

- Industrial Equipment: Reliable for transferring fluids in manufacturing setups.

- Transportation: Suitable for hydraulic systems in trucks and other vehicles.

- Offshore Operations: Designed to withstand harsh marine environments.

Their ability to perform under extreme conditions makes them a preferred choice for businesses seeking efficiency and reliability.

Note: Selecting the right thermoplastic hose ends can enhance system performance and reduce maintenance costs over time.

Advantages

Eaton’s thermoplastic hose ends come with several standout benefits that make them a popular choice across industries. Here are some of the key advantages:

- Durability: These hose ends feature a highly abrasion-resistant polyurethane cover. This ensures they can handle tough environments without wearing out quickly.

- Lightweight Design: The perforated cover reduces weight, making installation and handling much easier.

- High Pressure Performance: With an impressive impulse cycle life of 200,000 cycles, they perform reliably in high-pressure systems.

- Temperature Resistance: They operate effectively in temperatures as low as -40°F, making them suitable for cold climates or refrigerated systems.

- Flexibility: A minimum bend radius of just 0.81 inches allows them to fit into tight spaces effortlessly.

- Safety Compliance: Many of Eaton’s hose ends meet SAE 100R8 standards, ensuring they meet industry safety requirements.

Tip: For industries like hydraulics and offshore operations, these hose ends can reduce downtime and improve overall system efficiency.

Their combination of strength, flexibility, and compliance makes them a reliable choice for businesses seeking long-lasting solutions.

Disadvantages

While Eaton’s thermoplastic hose ends offer many benefits, they do have a few limitations that users should consider:

- Higher Initial Cost: These hose ends may cost more upfront compared to some alternatives. However, their durability often offsets this over time.

- Limited Temperature Range: Although they perform well in cold conditions, their upper temperature limit may not suit systems exposed to extreme heat.

- Specialized Applications: These hose ends are designed for specific industries. They might not be the best fit for low-pressure or non-industrial systems.

Note: Understanding your system’s requirements is crucial. Choosing the wrong hose ends could lead to inefficiencies or even system failures.

Despite these drawbacks, Eaton’s thermoplastic hose ends remain a top choice for industries that prioritize performance and reliability.

Thermoplastic Hose Ends by Gates

Product Range and Key Offerings

Gates offers a robust lineup of thermoplastic hose ends designed to meet the needs of various industries. Their products are known for their reliability and innovative designs. Gates focuses on creating hose ends that are lightweight, durable, and easy to install. One of their standout offerings is the MegaSys™ line, which includes hose ends built for high-pressure hydraulic systems. These products are engineered to handle demanding applications while maintaining flexibility and strength.

Gates also provides a range of customizable options. Businesses can choose from different sizes, materials, and pressure ratings to find the perfect fit for their systems. This flexibility makes Gates a go-to choice for industries like agriculture, construction, and manufacturing.

Tip: If you need hose ends that combine durability with versatility, Gates has you covered.

Technical Specifications

Gates thermoplastic hose ends are built to deliver exceptional performance. Here’s a quick look at their key specifications:

| Specification | Value |

|---|---|

| Max Operating Pressure | 5000 PSI |

| Min Burst Pressure | 12000 PSI |

| Temperature Range | -40°F to 250°F |

| Cover Material | Nylon or Polyurethane |

| Inner Core Material | Seamless thermoplastic tube |

| Reinforcement | High-tensile synthetic fiber |

| Bend Radius | As low as 1 inch |

These specifications highlight the strength and adaptability of Gates hose ends. The seamless thermoplastic tube ensures smooth fluid transfer, while the high-tensile fiber reinforcement adds durability. With a temperature range extending up to 250°F, these hose ends can handle extreme conditions with ease.

Applications and Use Cases

Gates thermoplastic hose ends are versatile and find applications across a wide range of industries. Here are some common use cases:

- Agriculture: Perfect for irrigation systems and hydraulic machinery.

- Construction: Reliable for heavy equipment like excavators and loaders.

- Manufacturing: Ideal for transferring lubricants and other fluids in industrial setups.

- Automotive: Suitable for hydraulic systems in vehicles.

Their ability to perform under high pressure and in extreme temperatures makes them a trusted choice for businesses seeking efficiency and reliability.

Note: Choosing the right thermoplastic hose ends can significantly improve system performance and reduce downtime.

Advantages

Gates thermoplastic hose ends offer several standout benefits that make them a reliable choice for industries. Here’s why they’re worth considering:

- High Pressure Capability: These hose ends can handle up to 5,000 PSI operating pressure and 12,000 PSI burst pressure. That’s perfect for demanding hydraulic systems.

- Wide Temperature Range: With a range from -40°F to 250°F, they perform well in both freezing and hot conditions. This versatility makes them suitable for diverse environments.

- Durable Materials: Gates uses nylon and polyurethane for the cover, ensuring abrasion resistance and long-lasting performance.

- Flexible Design: A bend radius as low as 1 inch allows these hose ends to fit into tight spaces. This flexibility is ideal for complex setups.

- Customizable Options: Businesses can choose from various sizes and materials to match their specific needs. This adaptability makes Gates a favorite among industries like agriculture and construction.

Tip: If your system operates in extreme temperatures or high-pressure conditions, Gates hose ends can help improve efficiency and reduce downtime.

Their combination of strength, flexibility, and adaptability makes them a smart investment for businesses seeking reliable fluid transfer solutions.

Disadvantages

While Gates thermoplastic hose ends shine in many areas, they do have a few limitations:

- Higher Initial Cost: These hose ends may cost more upfront compared to some alternatives. However, their durability often offsets this expense over time.

- Specialized Applications: Gates designs these hose ends for specific industries. They might not be the best fit for low-pressure or non-industrial systems.

- Potential Weight Concerns: Although lightweight overall, some configurations may add extra weight to systems, which could impact certain applications.

Note: Understanding your system’s requirements is crucial. Choosing the wrong hose ends could lead to inefficiencies or even system failures.

Despite these drawbacks, Gates thermoplastic hose ends remain a top choice for industries that prioritize performance and reliability.

Thermoplastic Hose Ends by Kurt Manufacturing

Product Range and Key Offerings

Kurt Manufacturing, through its Kurt Hydraulics division, delivers a comprehensive lineup of hydraulic hoses and couplings, including thermoplastic options. With over 35 years of experience in coupling manufacturing, the company has built a reputation for reliability and innovation. All their products adhere to SAE specifications, ensuring consistent quality and performance.

Here’s what sets Kurt Manufacturing apart:

- A complete range of hydraulic hoses and couplings tailored to various industries.

- Decades of expertise in designing and manufacturing coupling solutions.

- Products built to meet or exceed SAE standards for safety and durability.

Tip: If you’re looking for dependable thermoplastic hose ends backed by decades of expertise, Kurt Manufacturing is a solid choice.

Technical Specifications

Kurt Manufacturing’s thermoplastic hose ends are engineered for durability and high performance. Their construction and specifications make them suitable for demanding applications.

| Specification/Metric | Details |

|---|---|

| Construction | Thermoplastic nylon inner tube, synthetic textile braiding, urethane cover |

| Pressure Ratings | R7: 1,000 – 3,000 psi working pressure; R8: 3,500 – 5,000 psi working pressure; R18: 3,000 psi working pressure |

| Minimum Burst Pressure | R7: 4,000 – 12,000 psi; R8 and R18: varies by type |

| Size Availability | R7: 1/8 in. I.D. to 1 in. I.D.; R8 and R18: various sizes from 3/16 to 1/2 in. I.D. |

| Working Temperature Range | -40 to 212°F |

| Resistance | Abrasion, ozone, and weather resistant |

| Special Features | Nonconductive versions available for electrical isolation; specialty multi-hose setups |

| Applications | Suitable for medium to high pressure hydraulic systems in various industries |

These specifications highlight the versatility and strength of Kurt Manufacturing’s thermoplastic hose ends. Their abrasion-resistant urethane cover and nonconductive options make them ideal for specialized applications.

Applications and Use Cases

Kurt Manufacturing’s thermoplastic hose ends excel in medium to high-pressure hydraulic systems. Their robust design and resistance to harsh conditions make them a reliable choice across industries.

Common applications include:

- Agriculture: Perfect for hydraulic systems in tractors and other machinery.

- Construction: Reliable for heavy equipment like excavators and loaders.

- Industrial Equipment: Suitable for transferring fluids in manufacturing setups.

- Transportation: Ideal for hydraulic systems in trucks and other vehicles.

Note: Their nonconductive versions are especially useful in environments requiring electrical isolation, such as certain industrial or transportation systems.

Kurt Manufacturing’s thermoplastic hose ends combine durability, flexibility, and safety, making them a trusted solution for businesses seeking long-lasting performance.

Advantages

Kurt Manufacturing’s thermoplastic hose ends offer several benefits that make them a standout choice for many industries. Here’s why they’re worth considering:

- Durable Construction: These hose ends feature a urethane cover that resists abrasion, ozone, and weather. This makes them ideal for tough environments.

- Wide Pressure Range: With working pressures ranging from 1,000 to 5,000 psi, they handle medium to high-pressure systems with ease.

- Nonconductive Options: For industries requiring electrical isolation, Kurt offers nonconductive versions. These are especially useful in sensitive environments.

- Temperature Resilience: They operate effectively between -40°F and 212°F, making them suitable for both cold and moderate heat conditions.

- Versatile Applications: From agriculture to transportation, these hose ends adapt to a variety of industries and tasks.

Tip: Businesses looking for reliable performance in demanding conditions will find Kurt’s thermoplastic hose ends a dependable solution.

Their combination of durability, flexibility, and safety features makes them a smart investment for industries that prioritize long-term reliability.

Disadvantages

While Kurt Manufacturing’s thermoplastic hose ends excel in many areas, they do have a few limitations that users should keep in mind:

- Limited High-Temperature Capability: Their maximum operating temperature of 212°F may not suit systems exposed to extreme heat.

- Higher Initial Cost: These hose ends might cost more upfront compared to some alternatives. However, their durability often offsets this over time.

- Specialized Applications: They are designed for medium to high-pressure systems. Businesses with low-pressure needs might find them unnecessary.

Note: Understanding your system’s specific requirements is crucial. Choosing a product that doesn’t align with your needs could lead to inefficiencies or additional costs.

Despite these drawbacks, Kurt Manufacturing’s thermoplastic hose ends remain a top choice for industries that demand durability and performance.

Comparison of Thermoplastic Hose Ends

Key Differences in Technical Specifications

When comparing thermoplastic hose ends from leading manufacturers, their technical specifications reveal distinct strengths tailored to specific applications. Here’s a breakdown of the measurable criteria:

| Manufacturer | Maximum Operating Pressure | Temperature Range | Material Properties |

|---|---|---|---|

| Supplier 1 | 2,500 PSI | -40°F to 212°F | Excellent resistance to abrasion, chemicals, and UV rays |

| SPIR STAR® | 3,600 PSI to 58,000 PSI | N/A | Spiralized steel wire reinforcements |

| Kurt Hydraulics | Up to 5,000 PSI WP | N/A | Three-layer construction with nylon inner tubes |

| Thomasnet | 200 PSI to 10,000 PSI | N/A | Resistant to abrasion, chemicals, and UV |

Each manufacturer brings unique features to the table. For instance, SPIR STAR® specializes in ultra-high-pressure applications, while Kurt Hydraulics focuses on medium to high-pressure systems with durable multi-layer construction. Supplier 1 and Thomasnet emphasize chemical and UV resistance, making their products ideal for industries like agriculture and food processing.

Tip: Matching the technical specifications to your system’s requirements ensures optimal performance and longevity.

Applications and Industry Suitability

Thermoplastic hose ends are versatile, but their suitability varies across industries. Here’s how different manufacturers align with specific applications:

- Supplier 1: Commonly used in construction, agriculture, and mining due to their abrasion and chemical resistance.

- SPIR STAR®: A favorite in the waterjet industry and oil & gas applications, thanks to their high-pressure capabilities.

- Kurt Hydraulics: Ideal for forklifts, machine tools, and man-lift systems, where durability and flexibility are crucial.

- Thomasnet: Perfect for food and beverage transfer, chemical handling, and paint spraying, where safety and customization matter.

Thermoplastic hose ends made from polyamides and HDPE also excel in preventing hydrogen permeation, making them suitable for high-pressure hydrogen transmission systems. Their multi-layer structure enhances durability, ensuring reliable performance under extreme conditions.

Note: Selecting the right hose ends for your industry can reduce downtime and improve system efficiency.

Pros and Cons Summary

Every manufacturer offers unique advantages and limitations. Here’s a comparative overview:

| Aspect | Pros | Cons |

|---|---|---|

| General Advantages | Lightweight, flexible, resistant to harsh environments | Temperature range restrictions, customization issues |

| 100R7 Thermoplastic Hose | High resistance to abrasion, chemicals, UV | Not suitable for extremely high temperatures, variable customization options |

| SPIR STAR® High-Pressure Hoses | High-quality materials, certified manufacturing | Limited to high-pressure applications, potentially higher cost |

| Thomasnet Thermoplastic Hoses | Resistant to abrasion, chemicals, UV, customizable | Limited temperature range, potential chemical compatibility issues |

Thermoplastic hose ends stand out for their lightweight design and adaptability. However, temperature range limitations and customization challenges can impact their suitability for certain systems. SPIR STAR® excels in high-pressure environments but may not be cost-effective for general applications. Thomasnet’s products offer excellent resistance and customization but might face compatibility issues with specific chemicals.

Tip: Weighing the pros and cons of each manufacturer helps businesses make informed decisions based on their operational needs.

Choosing the right thermoplastic hose ends can make a big difference in system performance and reliability. Each manufacturer offers unique strengths, from Parker’s abrasion-resistant designs to Gates’ high-pressure capabilities. The comparison highlights how factors like pressure ratings, temperature ranges, and material durability play a role in finding the best fit.

For industries with high-pressure needs, Eaton or Gates might be the way to go. If flexibility and customization are priorities, Dyna Flex or Kurt Manufacturing could be better options. Always match the product to your system’s requirements for the best results.

FAQ

What makes thermoplastic hose ends better than rubber ones?

Thermoplastic hose ends are lighter, more flexible, and resistant to chemicals. They also last longer in harsh environments. Rubber options may wear out faster, especially in extreme temperatures or when exposed to corrosive fluids.

Tip: For durability and efficiency, thermoplastic hose ends are often the smarter choice.

Can thermoplastic hose ends handle high-pressure systems?

Yes, most thermoplastic hose ends are designed for high-pressure applications. Some models, like those from Gates or Eaton, can handle up to 5,000 PSI or more. Always check the product’s specifications to match your system’s pressure requirements.

Are thermoplastic hose ends eco-friendly?

Many thermoplastic hose ends are recyclable, making them a greener option. Their durability also reduces waste from frequent replacements. This aligns with sustainability goals in industries like agriculture and manufacturing.

♻️ Note: Choosing recyclable materials helps reduce your environmental footprint.

How do I choose the right thermoplastic hose end for my system?

Start by identifying your system’s pressure, temperature, and fluid compatibility needs. Then, compare specifications from top manufacturers like Parker or Dyna Flex. Customizable options can also help meet unique requirements.

Do thermoplastic hose ends work in extreme temperatures?

Most thermoplastic hose ends perform well in cold conditions, often down to -40°F. However, their upper temperature limits vary. For example, Gates products can handle up to 250°F, while others may cap at 122°F.

Pro Tip: Always check the temperature range before purchasing.

Post time: Jun-12-2025