A hydraulic fitting is a connecting element between a hydraulic pipe and a hydraulic pipe, or between a pipe and a hydraulic element. A hydraulic fitting consists of a hydraulic fittingst for a hose and a hydraulic fittings for tube assembly, the hydraulic hose connector connects one section of the hydraulic hose (called the tail end) and the other end to other components (terminals) to ensure compatibility and leak-free sealing in connection with other components, the terminal of hydraulic hose joint should be designed according to the universal interface standard. The main function of the terminal is to ensure the long-term sealing between the fittings and the hose.

From the interface can be divided into the following forms:

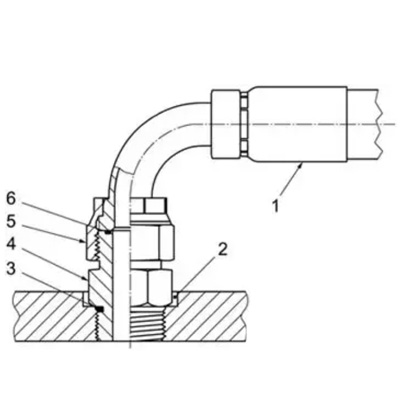

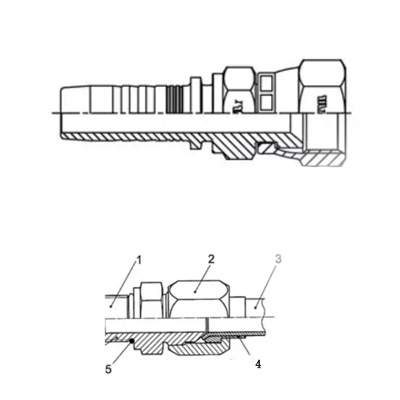

1. O-ring face seal hose fittings

1.Hose couplings 2. Oil Port 3. O-ring 4. Adaters 5. Nuts 6. O-ring

when the nut 5 is screwed to the external thread of the fittings, with the increase of the tightening moment, the end face of the hose fittings and the adapters (piece 4) compresses, the o-ring of the 4-end face of the fittings produces elastic deformation, and fully contacts the 4-end face of the piece 6 and the piece 4 and produces pressure to seal.

Special attention should be paid to the installation process, check the sealing ring before installation.

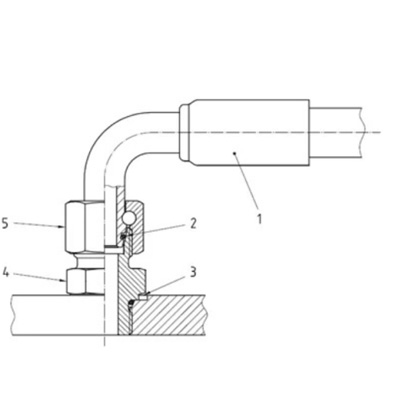

2.24 ° taper seal end hose connector

- Hose couplings 2. O-ring 3. Oil Port 4. Adapter 5. The nut

when the nut 5 is screwed to the external thread of the adapter -Partpart 4) , the outer cone surface of the hose fitting and the inner cone surface of the fitting b-Partdy (part 4) contact and compress with the increase of the tightening moment, the o-ring of the outer conical surface of the hose fittings 1 produces elastic deformation, fully contacts with the conical surfaces of the part 6 and the part 4 and produces a larger pressure, which acts as a seal, and the pressure between the conical surfaces is larger because of the lever action of the conical surfaces, the sealing effect is better in theory.

Special attention should be paid to the installation process, check the sealing ring before installation.

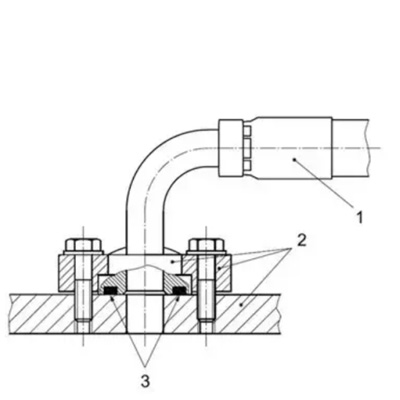

3.Flanged end hose fittings

1.Hose couplings 2. Oil nozzle, flange head, flange pressure plate 3.The flange head of the hose joint is pressed on the oil orifice by the flange pressure plate.

When the tightening moment of the bolt increases, the bolt produces a large pre-tightening force. The pre-tightening force of the bolt passes through the flange pressure plate, pressing the flange head tightly on the oil orifice, the o-ring (Part 3) on the flange head is pressed to deform, and the hose joint -Partpart 1) has sufficient contact between the flange end face and the oil nozzle surface to produce pressure, which acts as a seal, due to the use of high-strength bolts, the pressure between the contact surfaces is very high and the sealing effect is very good in theory.

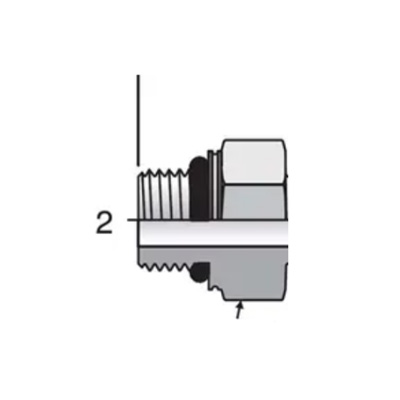

4. Stud end hose fittings

The root of the thread of the adapter is provided with an O-type washer. When the joint is connected with the oil port through the thread, the O-type ring adheres to the end face of the oil port to play a sealing role.

5.37 ° flared end hose connector

1. Hose couplings 2. NUTS 3. Steel Pipe 4. Bushing,

when the nut 2 is screwed on the external thread of the joint body (piece 1) , with the increase of the tightening moment, the outer cone surface of the hose joint contacts and compacts with the inner cone surface of the steel pipe (piece 3) , hose joint 1 piece 3 cone full contact and produce greater pressure, play a sealing role, because of the cone of the lever, the pressure between the cone is greater. In the process of choosing hydraulic pipe joint, we need to consider the maximum working pressure, working temperature, interface size, suitable pipe size, whether the installation is convenient, economic and other factors. The maximum working pressure of the joint shall not be lower than the maximum working pressure of the hose.

Post time: Nov-28-2023