Stainless steel pipe fittings bring unmatched durability to hydraulic systems. They resist corrosion and prevent leaks, even in harsh environments. Stainless steel fittings withstand pressure surges and reduce wear and tear. Hydraulic fittings made from stainless steel help maintain system cleanliness. These features protect against common failure modes and ensure long-lasting performance.

Key Takeaways

- Stainless steel pipe fittings resist corrosion and handle high pressure, making hydraulic systems safer and more reliable.

- These fittings last longer and need less maintenance, which saves money and reduces system downtime.

- Using stainless steel fittings meets industry standards and supports future-proof, eco-friendly hydraulic systems.

Stainless Steel Pipe Fittings in Hydraulic Systems

What Are Hydraulic Pipe Fittings?

Hydraulic pipe fittings play a vital role in fluid power systems. These components connect tubes, pipes, and hoses, allowing hydraulic fluid to move between power sources and application points. Different types of fittings serve specific functions:

- Threaded connectors join pipes and fittings, often used in low-pressure systems.

- Flanged connectors use bolted flanges for secure connections across various pressures.

- Welded connectors create strong, permanent joints for high-pressure applications.

- Brazed connectors join nonferrous piping, suitable for moderate pressure and temperature.

- Flared connectors form leak-resistant joints without threading or welding, common with tubing.

Each type helps maintain system integrity, supports easy maintenance, and enables customization for different hydraulic needs.

Impact on System Performance

The choice of hydraulic pipe fittings directly affects system efficiency and safety. Properly matched hoses and fittings keep hydraulic pumps working at high efficiency, often between 90% and 98%. When fittings do not match or are the wrong size, flow rates change. This can cause pressure spikes, damage machinery, and create safety risks for workers.

Selecting the right material also matters. The table below shows how different materials compare:

| Material | Advantages | Suitable Applications |

|---|---|---|

| Brass | Corrosion-resistant, easy to machine | Low to medium-pressure systems |

| Carbon Steel | Strong, cost-effective | General-purpose hydraulic systems |

| Stainless Steel | Highly durable, corrosion-resistant | High-pressure, high-temperature systems |

Stainless Steel Pipe Fittings offer the best performance in demanding environments. They resist corrosion and handle high pressures, making them ideal for modern hydraulic systems.

Key Advantages of Stainless Steel Pipe Fittings

Corrosion Resistance

Stainless Steel Pipe Fittings stand out for their exceptional resistance to corrosion. This property comes from the chromium in the steel, which forms a protective oxide layer on the surface. In hydraulic systems, this layer shields the fittings from rust and chemical attack. The 316 grade, with added molybdenum, offers even better protection against saltwater and harsh chemicals. These fittings work well in marine, chemical, and food industries, where exposure to aggressive fluids is common.

Note: Stainless steel fittings require less maintenance and last longer than brass or carbon steel fittings. They do not need protective coatings, which saves time and money.

A comparison of corrosion resistance from laboratory and field tests:

| Material/Coating | Test Type | Corrosion Resistance Result |

|---|---|---|

| Brennan’s CR3 Plating | Lab test | 120 hours to white rust, 240 hours to red rust |

| Zinc Nickel Blend | Independent lab test | 360 hours to white rust, 504 hours to red rust |

| Brennan Black® | Lab and field tests | >1700 hours red rust resistance |

| Stainless Steel | Statement only | Ultimate corrosion resistance; excellent chemical resistance |

Stainless Steel Pipe Fittings provide the highest level of corrosion resistance, making them a reliable choice for demanding environments.

High-Pressure and Temperature Tolerance

Hydraulic systems often operate under high pressure and temperature. Stainless Steel Pipe Fittings handle these conditions with ease. They can withstand pressures up to 10,000 psi, and some specialized fittings go even higher. The material remains strong across a wide temperature range, from freezing cold to extreme heat.

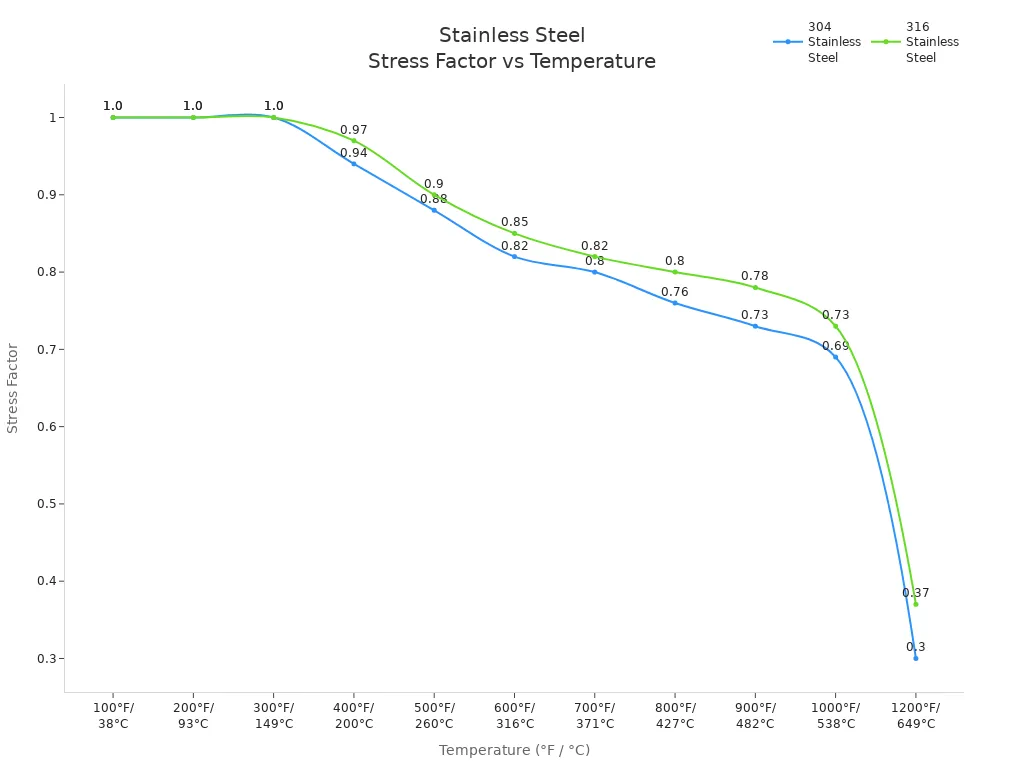

The following table shows how temperature affects the strength of 304 and 316 stainless steel:

| Temperature (°F / °C) | 304 Stainless Steel Stress Factor | 316 Stainless Steel Stress Factor |

|---|---|---|

| 100 / 38 | 1.00 | 1.00 |

| 400 / 200 | 0.94 | 0.97 |

| 800 / 427 | 0.76* | 0.80* |

| 1200 / 649 | 0.30* | 0.37 |

*Above 800°F (427°C), special care is needed due to possible corrosion.

Stainless steel fittings keep their integrity during pressure surges and thermal cycling. They resist deformation and seal failure, even when temperatures change quickly.

Strength and Longevity

Stainless Steel Pipe Fittings offer high strength and long service life. They have excellent mechanical properties, such as high tensile strength and resistance to deformation. These fittings can handle heavy loads and frequent pressure changes without cracking or breaking.

- Stainless steel fittings last longer than brass or carbon steel fittings.

- They require less maintenance and have longer intervals between replacements.

- The service life of stainless steel fittings can exceed 50 years in many hydraulic systems.

Stainless steel’s strength allows for thinner walls compared to carbon steel, reducing weight while maintaining durability. This makes them suitable for both compact and heavy-duty hydraulic applications.

Leak Prevention and System Reliability

Leak prevention is critical in hydraulic systems. Stainless Steel Pipe Fittings use several design features to ensure tight, leak-free connections:

- High working pressure ratings with built-in safety factors.

- Precision machining for accurate fit and secure connections.

- Advanced sealing mechanisms, such as metal-to-metal seals and O-ring face seals, that prevent leaks under vibration and pressure changes.

- Tapered threads and double ferrule compression fittings for extra sealing strength.

| Design Feature | Description and Leak Prevention Role |

|---|---|

| Robust Construction | Heavy-duty materials and sturdy build reduce risk of failure and leaks. |

| Enhanced Sealing | Double ferrule compression fittings, O-rings, and metal-to-metal seals ensure tight seals under extreme pressure. |

| Precision Machining | Tight tolerances ensure secure, leak-free connections. |

| Tapered Threading Design | Threads compress when tightened, creating a secure, leak-resistant fit. |

| Reinforced Connections | Thicker walls or extended nuts provide extra strength and support. |

| Material Selection | Stainless steel offers strength and corrosion resistance, essential for maintaining integrity under pressure. |

| Compliance and Testing | Adherence to industry standards and rigorous testing ensure reliability and leak prevention. |

Stainless steel fittings help maintain system reliability in mission-critical applications. Their durability, high pressure ratings, and excellent sealing reduce maintenance needs and system downtime.

Future-Proofing with Stainless Steel Pipe Fittings

Industry Trends and Standards in 2025

Hydraulic systems in 2025 will see big changes in material selection and technology. Companies now choose materials that improve system reliability and reduce stress on fittings. Many industries want eco-friendly and lightweight materials that last longer and work better. New trends include smart hydraulic hoses with sensors for real-time monitoring and early failure detection. Digital technologies like IoT help with predictive maintenance, making systems safer and more efficient.

Manufacturers must follow strict safety and environmental rules. International standards such as ISO and API require high-quality, corrosion-resistant materials. Stainless Steel Pipe Fittings meet these standards, helping companies avoid fines and keep workers safe. These fittings also work well with global systems, making them a smart choice for future needs.

Note: Using fittings that meet international standards helps prevent leaks, reduces pressure drops, and keeps hydraulic systems running smoothly.

Versatility Across Applications

Stainless steel fittings work in many industries because they handle high pressure, extreme temperatures, and harsh environments.

Some common uses include:

- Marine: Shipbuilding and oil rigs need fittings that resist saltwater and corrosion.

- Food Processing: Pumps and valves require easy cleaning and hygiene.

- Pharmaceutical: Reactors and mixers need high purity and chemical resistance.

- Construction: Heavy equipment like cranes and excavators need strength and durability.

- Chemical Processing: Plants need fittings that last in tough chemical environments.

A table shows how these fittings adapt to different standards:

| Industry/Region | Standard/Type | Key Feature |

|---|---|---|

| American | SAE, NPT | Leak-proof, high-pressure sealing |

| European/Global | BSP, ISO | Compatibility, corrosion resistance |

| Japanese/German | JIS, DIN | Specialized sealing, durability |

Sustainability and Environmental Benefits

Stainless steel fittings support sustainability in several ways. They are 100% recyclable and often made with recycled materials. This reduces waste and saves natural resources. The forging process creates less scrap and uses less energy than other methods.

These fittings last a long time, so companies replace them less often. This lowers maintenance costs and reduces the need for new materials. Stainless steel’s durability and corrosion resistance mean fewer leaks and less environmental harm.

Many industries now choose stainless steel to meet strict environmental rules and support a circular economy.

- Stainless steel fittings deliver reliability and safety in hydraulic systems.

- Their strength and corrosion resistance support high-pressure performance and long service life.

- Industry standards and expert endorsements confirm their value for future-proof assemblies.

- Companies benefit from fewer repairs, lower costs, and consistent system efficiency.

FAQ

What makes stainless steel pipe fittings better for hydraulic systems?

Stainless steel fittings resist corrosion and handle high pressure. They last longer than other materials. Many industries choose them for safety and reliability.

Can stainless steel pipe fittings be recycled?

Yes. Stainless steel is 100% recyclable. Many manufacturers use recycled material to make new fittings. This helps protect the environment and saves resources.

Where can stainless steel pipe fittings be used?

Engineers use stainless steel fittings in construction, marine, food processing, and chemical plants. These fittings work well in places with high pressure, temperature, or harsh chemicals.

Post time: Jul-24-2025